When the ambient humidity exceeds 85% relative humidity, this relay may encounter a series of performance problems and potential failures that not only affect its normal operation but may also adversely affect the entire electrical system. In a high-humidity environment, a water film is easily formed on the surface of the relay contacts, which will significantly affect the contact resistance of the contacts. The existence of the water film increases the gap between the contacts, resulting in insufficient contact pressure and poor contact. Poor contact may result in unstable signal transmission or even complete failure. If exposed to a high humidity environment for a long time, corrosion or oxidation may occur on the contact surface, forming a thin film with poor conductivity. This film will further increase contact resistance and reduce the reliability of the electrical connection.

The insulating material inside the relay will absorb moisture in a high-humidity environment, causing the insulation resistance to decrease. The reduction in insulation resistance may cause leakage, and in serious cases may lead to short circuit, posing a threat to the safety of the electrical system. Long-term high humidity environment will accelerate the aging process of insulation materials, leading to further deterioration of insulation performance. Aging insulation materials may lose their original elasticity and strength and cannot effectively isolate current, increasing the risk of electrical failure.

The metal components inside the relay are prone to rust in high-humidity environments, which affects its mechanical performance and movement capabilities. Corroded parts may not maintain their original accuracy and stability, causing the relay to operate unreliably. A high-humidity environment may accelerate the fatigue process of the spring inside the relay, causing the spring's elastic force to weaken or fail. Spring fatigue will affect the contact pressure and operating speed of the contacts, thereby affecting the overall performance of the relay.

The combined effect of the above factors will accelerate the overall aging process of the relay, resulting in gradual performance degradation. Aging relays may not be able to meet the requirements of the electrical system and require frequent replacement or repair, increasing operation and maintenance costs. In some special application environments (such as oceans, deserts and other extreme climate areas), the humidity may far exceed the relative humidity of 85%. These environments pose higher challenges to the performance of the relay, requiring additional protective measures to ensure the stable operation of the relay.

When the ambient humidity exceeds 85% relative humidity, this relay may face a series of performance issues and potential failures. By taking appropriate countermeasures, these risks can be effectively reduced to ensure stable operation and extended service life of the relay.

Web Menu

Product Search

Exit Menu

news

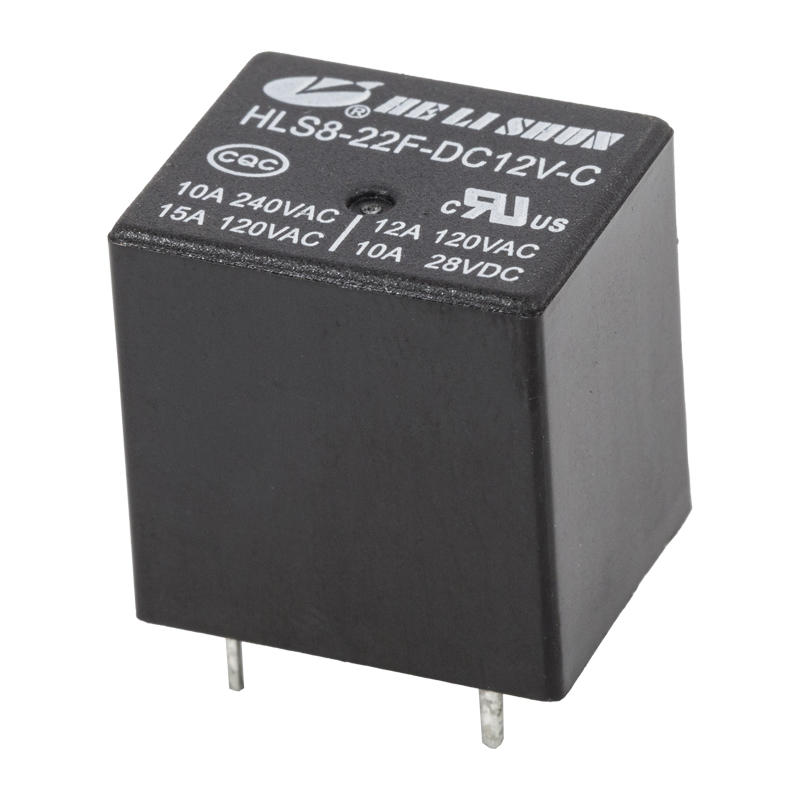

Home / News / Industry News / What performance issues or failures might occur with this relay if the ambient humidity exceeds 85% relative humidity?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhat performance issues or failures might occur with this relay if the ambient humidity exceeds 85% relative humidity?

Posted by Admin | 29 Nov

PREV:How to prevent relay sockets from overheating during design and use?

NEXT:What failure modes may occur in automotive relays under high temperature environments?

NEXT:What failure modes may occur in automotive relays under high temperature environments?

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright © Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体