The possible failure modes and their effects of automotive relays under high temperature environments are a complex and critical issue. It is not only related to the normal operation of the automotive electrical system, but also directly affects the safety and reliability of the vehicle. High temperature environments accelerate the degradation process of the internal materials of the relay. These materials may gradually lose their original mechanical strength, electrical properties and chemical stability at high temperatures, resulting in a decrease in the overall performance of the relay. As one of the most critical components in the relay, the contact is prone to react with oxygen in the air at high temperatures to form an oxide layer. This layer of oxide will increase the contact resistance of the contact, reduce the conductivity, and even cause the contact to stick or be unable to separate.

When the relay contacts are closed, if the current passing through is too large or lasts too long, the contact surface may be ablated due to high temperature. The ablated contact surface becomes rough and uneven, further increasing the contact resistance and wear rate. At high temperatures, the contact material may deform due to thermal expansion and contraction, resulting in changes in the contact gap, affecting the closing and disconnection effects of the contacts.

Under high temperature environment, the mechanical parts inside the relay (such as springs, transmission mechanism, etc.) may become sluggish due to thermal expansion and contraction, resulting in a longer response time of the relay. The relay may become insensitive at high temperature and fail to accurately respond to control signals, causing the electrical system to fail to work properly.

High temperature may cause the insulation material inside the relay to age, crack or deform, thereby reducing its insulation performance. When the insulation fails, the circuit inside the relay may be damaged by a short circuit. Long-term high temperature environment may cause the wire inside the relay to melt due to overheating, causing the circuit to be broken.

Under high temperature, the spring may lose its elasticity due to material degradation, resulting in the contact not being able to close or open properly. The transmission mechanism may deform or get stuck due to thermal expansion and contraction at high temperature, affecting the normal operation of the relay.

If the relay adopts a sealed structure to prevent moisture and dust from entering, high temperature may cause the sealing material to age, crack or deform, thereby losing the sealing effect. After the seal fails, the inside of the relay is susceptible to pollution and erosion from the external environment, such as dust, moisture, corrosive gases, etc. These pollutants may adhere to the contacts and circuit boards, causing the relay to degrade or even fail.

To avoid these failure modes, you can choose high temperature resistant materials. When designing and manufacturing relays, choose high temperature resistant and stable performance materials and components. Optimize heat dissipation design. Improve the heat dissipation capacity of relays by improving the heat dissipation structure of relays, such as adding heat sinks and using materials with good thermal conductivity. Regular inspection and maintenance. Regularly inspect and maintain relays to detect and deal with potential failure problems in a timely manner. Use protection components. Consider using fuses, thermistors and other protection components in circuit design to limit current and temperature to prevent relays from being damaged by overheating.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / What failure modes may occur in automotive relays under high temperature environments?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhat failure modes may occur in automotive relays under high temperature environments?

Posted by Admin | 22 Nov

PREV:What performance issues or failures might occur with this relay if the ambient humidity exceeds 85% relative humidity?

NEXT:Is this power relay suitable for applications that require high current carrying capacity?

NEXT:Is this power relay suitable for applications that require high current carrying capacity?

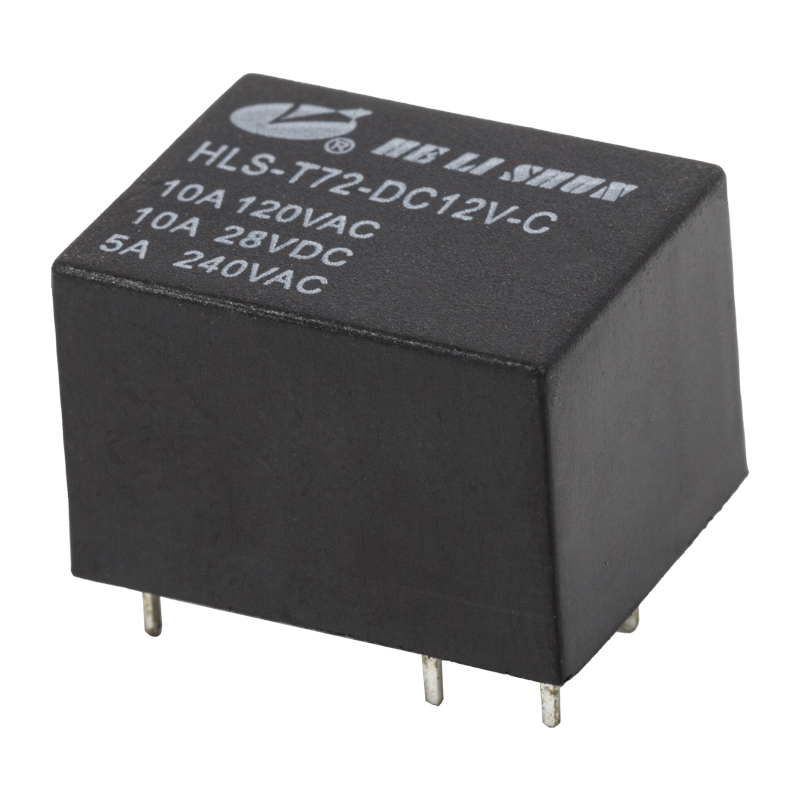

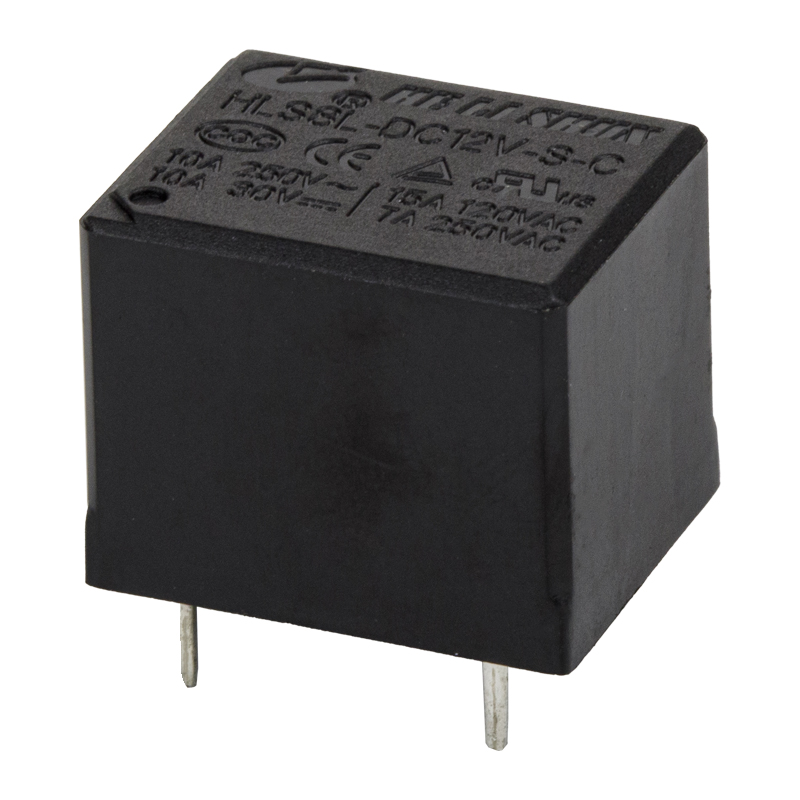

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体