In design and use, preventing relay sockets from overheating is a key link to ensure the stable operation of the circuit system, which requires us to take comprehensive measures at multiple levels. According to the specific needs of the circuit, accurately analyze the load type (AC or DC), rated current, voltage range, and possible peak current, and select relays that can withstand these parameters.

Give priority to relay models with superior heat dissipation performance, especially those with built-in heat sinks or special heat dissipation designs. At the same time, when designing, ensure that there is enough space around the relay socket to facilitate air circulation and promote heat dissipation. Add overload protection mechanisms to the circuit design, such as using thermal relays, fuses, or electronic overload protectors, to cut off the power supply in time when the current rises abnormally to prevent the relay socket from overheating.

In circuit board design, reasonably layout the relay socket and other electrical components to avoid heat concentration. Ensure that there are no obstacles around the relay socket that block heat dissipation. Use the copper traces on the circuit board as a heat dissipation path, or design special heat dissipation channels, such as opening ventilation holes and using heat sinks, to enhance the heat dissipation effect.

Relay sockets should be installed by professionals in accordance with the manufacturer's guidelines to ensure that the wiring is firm and the contact is good to avoid heating due to poor contact. Check the relay sockets regularly, including the wear of the contacts, the tightness of the connecting wires, and the integrity of the sockets themselves. If any abnormality is found, it should be replaced or repaired immediately. Keep the relay sockets and their surroundings clean, remove dust and debris regularly, and avoid dust accumulation affecting heat dissipation.

Ensure that the ambient temperature of the relay socket is within the operating range specified by the manufacturer. In extreme temperature conditions, additional cooling measures should be taken, such as installing fans or air conditioners. Maintain a suitable humidity level to avoid excessive or low humidity affecting the insulation performance and heat dissipation of the relay.

Distribute the load reasonably to avoid a single relay socket carrying too much current. For high-power loads, consider using multiple relays to share the load. For loads that are frequently started or run for a long time, consider implementing an intermittent working mode to reduce the heat accumulation of the relay. Introduce an intelligent monitoring system to monitor the working status and temperature of the relay socket in real time, and immediately alarm and take corresponding measures once an abnormality is found.

Through careful selection and optimized layout in the design stage, as well as correct installation, regular inspection, environmental control, load management and other efforts in the use stage, the relay socket can be effectively prevented from overheating and the safe, stable and efficient operation of the circuit system can be ensured.

Web Menu

Product Search

Exit Menu

news

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsHow to prevent relay sockets from overheating during design and use?

Posted by Admin | 06 Dec

PREV:For applications that require frequent switching operations, how is the mechanical durability of this high power relay, and does it meet industry standards?

NEXT:What performance issues or failures might occur with this relay if the ambient humidity exceeds 85% relative humidity?

NEXT:What performance issues or failures might occur with this relay if the ambient humidity exceeds 85% relative humidity?

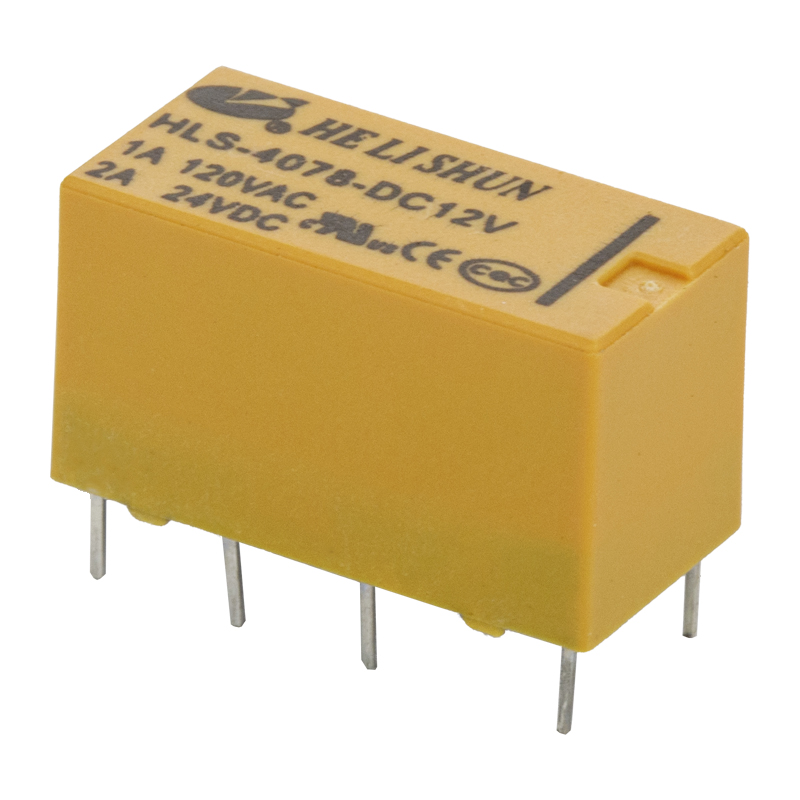

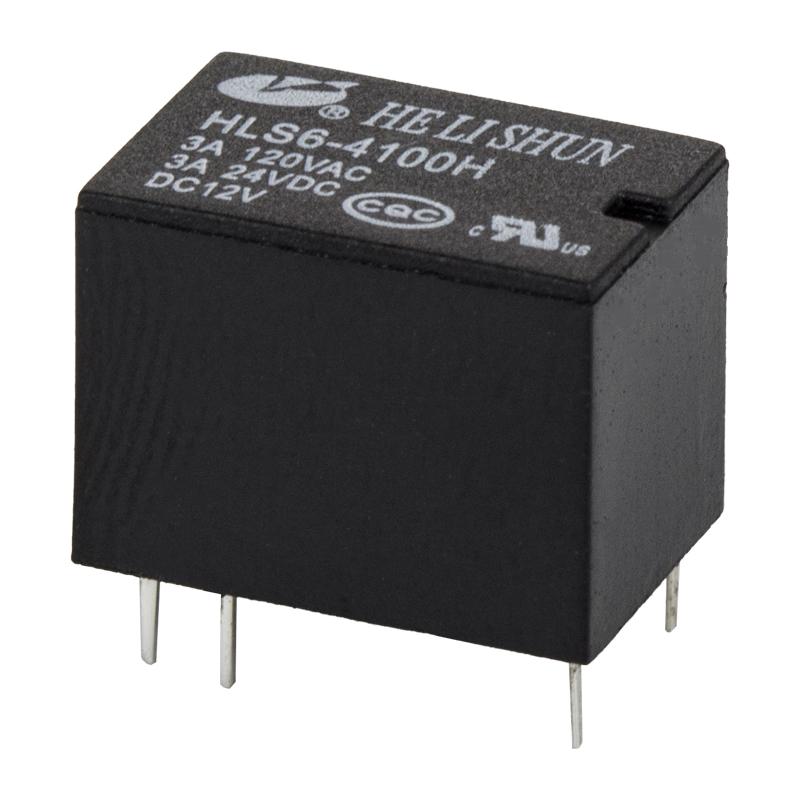

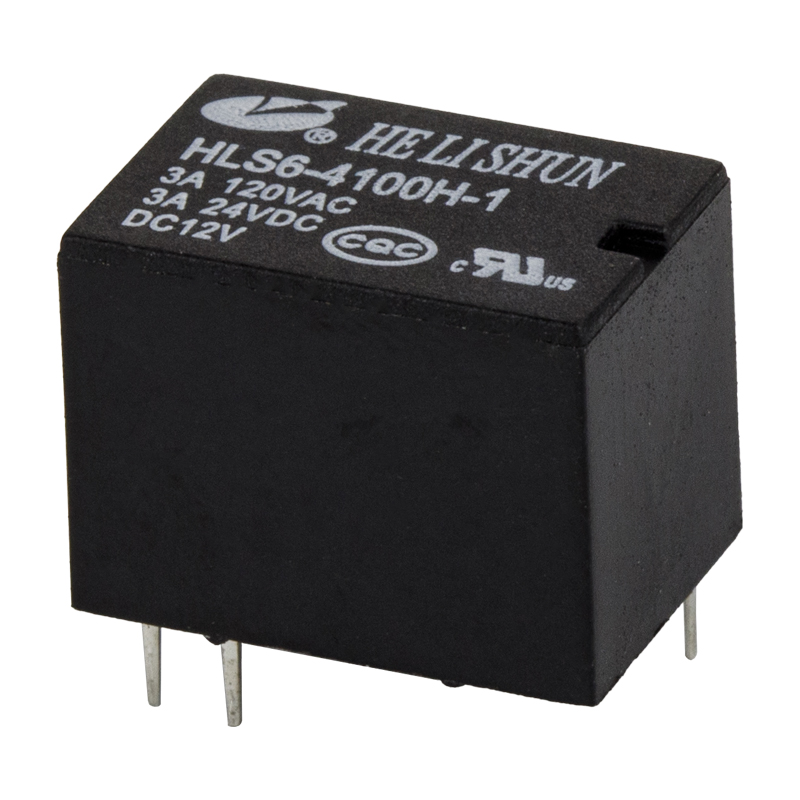

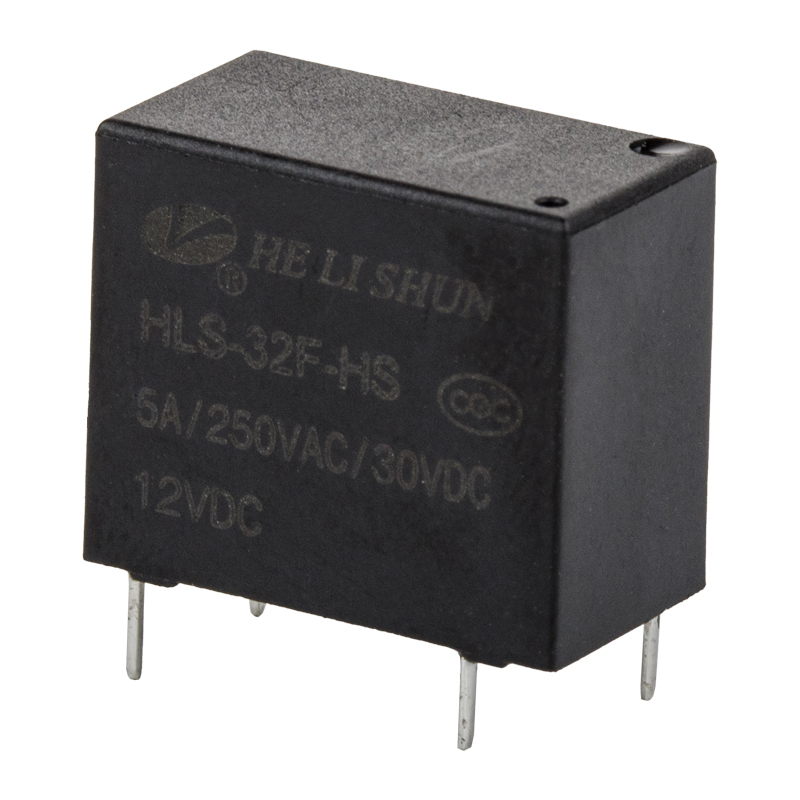

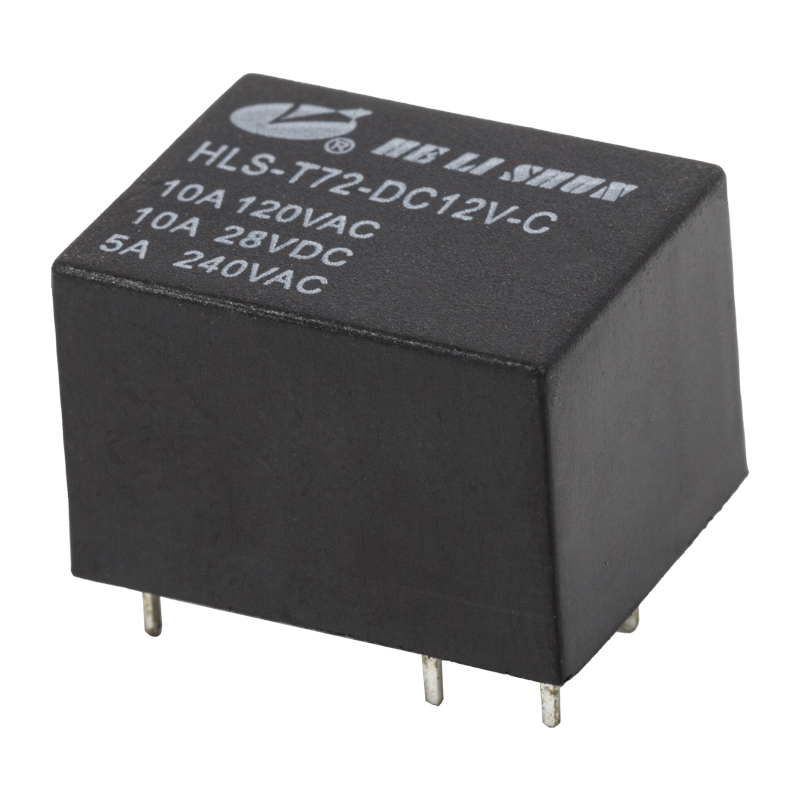

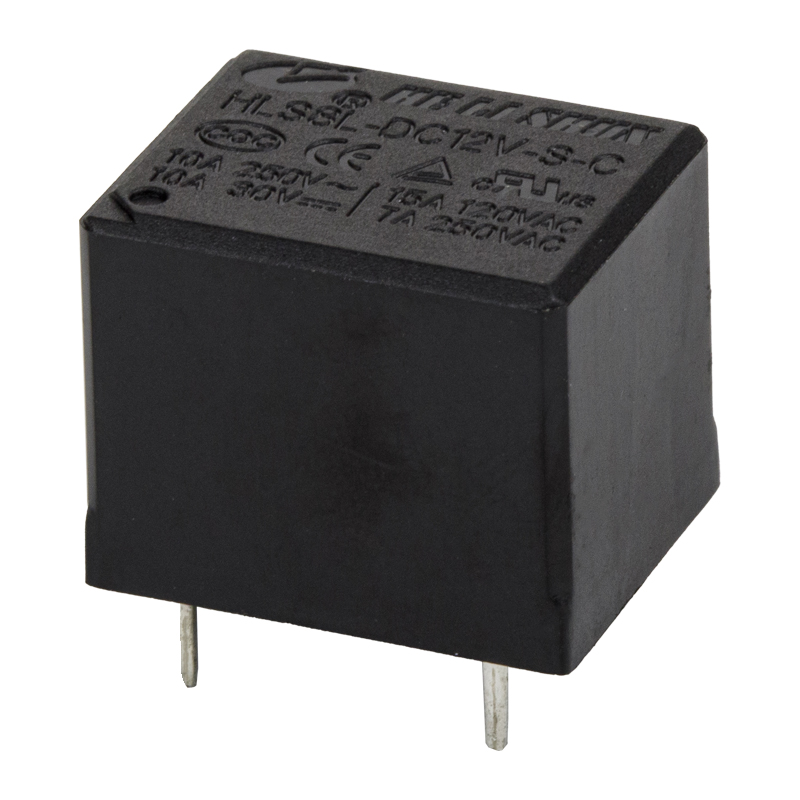

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体