When designing automotive relays, it is necessary to select materials that can withstand the specified humidity range. These materials should have good moisture resistance to prevent moisture penetration from causing internal circuit short circuits or corrosion. To ensure that the relay can still work normally in a humid environment, the design should consider the use of a sealed structure to reduce the impact of external moisture on internal components. The sealed structure can effectively prevent moisture and moisture from entering the interior of the relay and protect the internal circuit and contacts from damage.

As a key component in the relay, the material selection of the contact is particularly important. In a humid environment, the contact material needs to have good corrosion resistance and wear resistance to prevent poor contact or failure caused by oxidation or wear. High-quality contact materials such as silver alloys are often used in the design of automotive relays because of their good conductivity and corrosion resistance. Insulating materials play the role of isolating and protecting circuits in relays. In a humid environment, the performance of insulating materials may be affected, resulting in a decrease in insulation resistance or an increase in leakage current. Therefore, special treatment of insulating materials is required during design to improve their moisture resistance.

When using automotive relays, it is necessary to monitor the ambient humidity regularly to ensure that it is within the specified range. If the ambient humidity is too high, measures should be taken in time to reduce the humidity to avoid damage to the relay. Automotive relays used in humid environments require regular maintenance inspections to ensure that their internal components are not corroded or damaged. Maintenance inspections include cleaning contacts, checking the state of insulating materials, and testing relay performance.

The installation location of the relay should be away from moisture sources to reduce the impact of moisture on it. At the same time, during the installation process, it should be ensured that the relay maintains an appropriate distance and ventilation conditions from the surrounding components to dissipate heat and prevent moisture. In extremely humid environments, additional protective measures can be considered for the relay, such as installing a moisture-proof cover or using a moisture-proof agent. These measures can further improve the moisture-proof performance of the relay and ensure its stable operation in harsh environments.

The ambient humidity range puts forward many special requirements for the design and use of automotive relays. By selecting suitable materials, adopting a sealed structure design, regularly monitoring the ambient humidity, and taking necessary protective measures, the long-term stable operation of automotive relays in humid environments can be ensured.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / What special requirements does the environmental humidity range have for the design and use of automotive relays?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhat special requirements does the environmental humidity range have for the design and use of automotive relays?

Posted by Admin | 13 Aug

PREV:What impact will the increase in contact resistance of automotive relays have on the circuit?

NEXT:What measures do high power relays take to prevent oxidation or corrosion of contact materials?

NEXT:What measures do high power relays take to prevent oxidation or corrosion of contact materials?

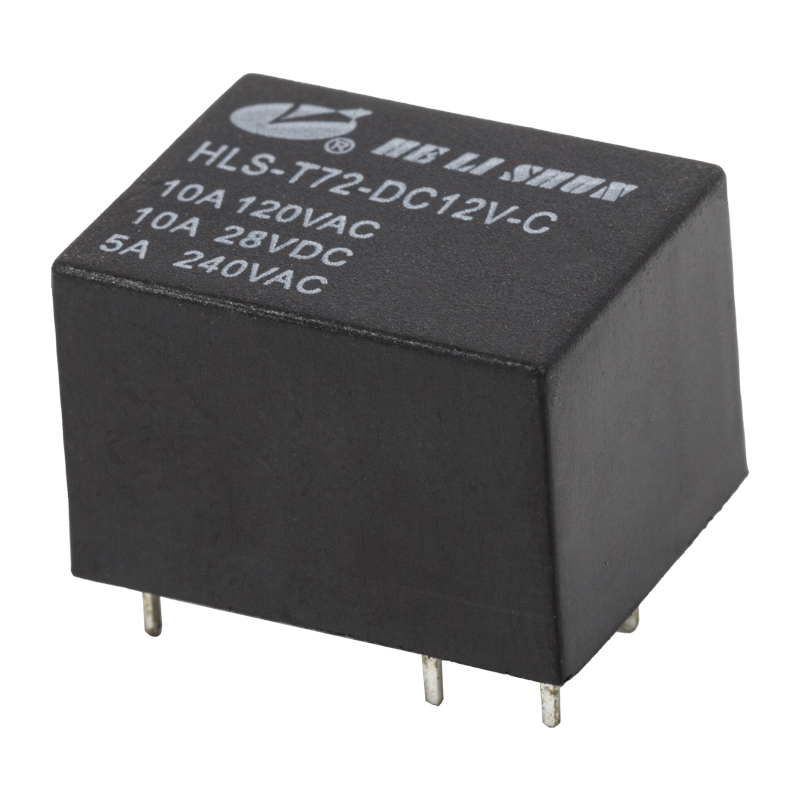

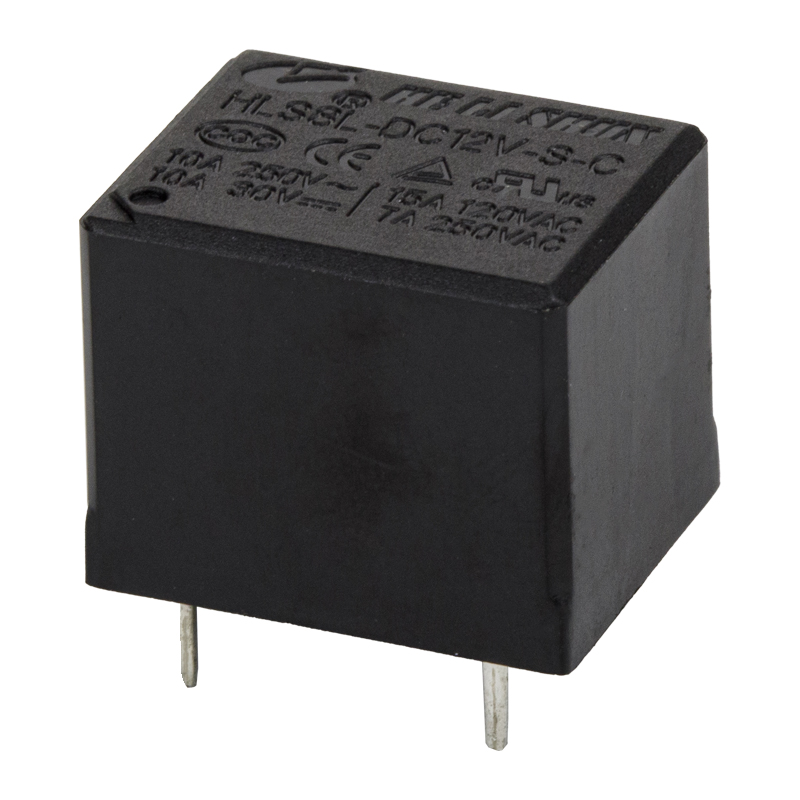

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体