Reduced Energy Efficiency: The contact resistance of an automotive relay is an obstacle to the passage of electricity, meaning that as electricity flows through the contacts, more electrical energy is converted to heat rather than used for its intended purpose. This energy conversion not only wastes valuable power resources, but also increases the overall energy consumption of the car, especially under high load or long-term operation conditions.

Reduced cruising range: For electric vehicles, cruising range is one of the performance indicators that users are most concerned about. When the contact resistance of the automotive relay increases, part of the electrical energy that should be supplied to the drive motor is consumed on the relay contacts, resulting in a reduction in the energy actually used for driving. This is directly reflected in the cruising range of electric vehicles, making the vehicles need to be charged more frequently during actual driving, thus reducing user travel convenience and satisfaction.

Local overheating: Local overheating is a direct consequence of increased contact resistance. High-temperature environments not only accelerate the physical and chemical changes of contact materials, but may also cause the temperature of surrounding electronic components to increase, thereby triggering thermal management challenges for the entire circuit system. In order to deal with this overheating problem, automotive designers need to adopt more efficient heat dissipation solutions, such as adding heat sinks and optimizing air duct design, to ensure the stable operation of the circuit system.

Thermal runaway risk: In extreme cases, if the temperature of the relay contacts continues to rise and is not effectively controlled, thermal runaway of the battery or other critical electronic components may occur. Thermal runaway will not only cause component damage, but may also cause serious safety accidents such as fires. Therefore, automakers must implement strict thermal management measures and redundant designs to ensure the safety of passengers and vehicles even in extreme conditions.

Increased voltage drop: The increase in contact resistance will cause the voltage drop across the contacts to increase, which may affect the normal operating voltage range of other components in the circuit. Especially in precision control systems, such as motor drives, sensor networks, etc., small voltage fluctuations may cause system performance degradation or failure. Therefore, maintaining low contact resistance of relay contacts is critical to maintaining the stability and reliability of the entire circuit system.

Signal distortion: In signal transmission circuits, increased contact resistance may also cause signal distortion or attenuation problems. This is unfavorable for situations where high-precision signal transmission is required. Signal distortion not only affects user experience, but may also lead to system misjudgment or failure. Therefore, when designing a signal transmission circuit, it is necessary to fully consider the impact of relay contact resistance and take appropriate measures to reduce the risk of signal distortion.

Welding risk: When the contact temperature reaches a certain level, the contact materials may soften or even fuse together, causing the relay to be unable to properly disconnect the circuit. This will not only destroy the normal working condition of the circuit, but may also cause more serious circuit failures or safety accidents. In order to prevent the occurrence of welding, it is necessary to select contact materials that are resistant to high temperatures and wear, and to reasonably design the heat dissipation structure and working conditions of the relay.

Shortened lifespan: Relay contacts that work under high temperature and high resistance for a long time will undergo rapid physical and chemical changes, resulting in changes in the surface morphology of the contacts and a reduction in the contact area. These changes will further exacerbate the increase in contact resistance and performance degradation. Over time, a relay's switching speed will slow down, its response time will increase, and its reliability will decrease, ultimately affecting its service life. Therefore, regular maintenance and replacement of relays is one of the important measures to ensure long-term and stable operation of the automotive circuit system.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / What impact will the increase in contact resistance of automotive relays have on the circuit?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhat impact will the increase in contact resistance of automotive relays have on the circuit?

Posted by Admin | 20 Aug

PREV:How to design the automotive relay PCB quick pin to ensure its stability and durability under high-frequency switching operation?

NEXT:What special requirements does the environmental humidity range have for the design and use of automotive relays?

NEXT:What special requirements does the environmental humidity range have for the design and use of automotive relays?

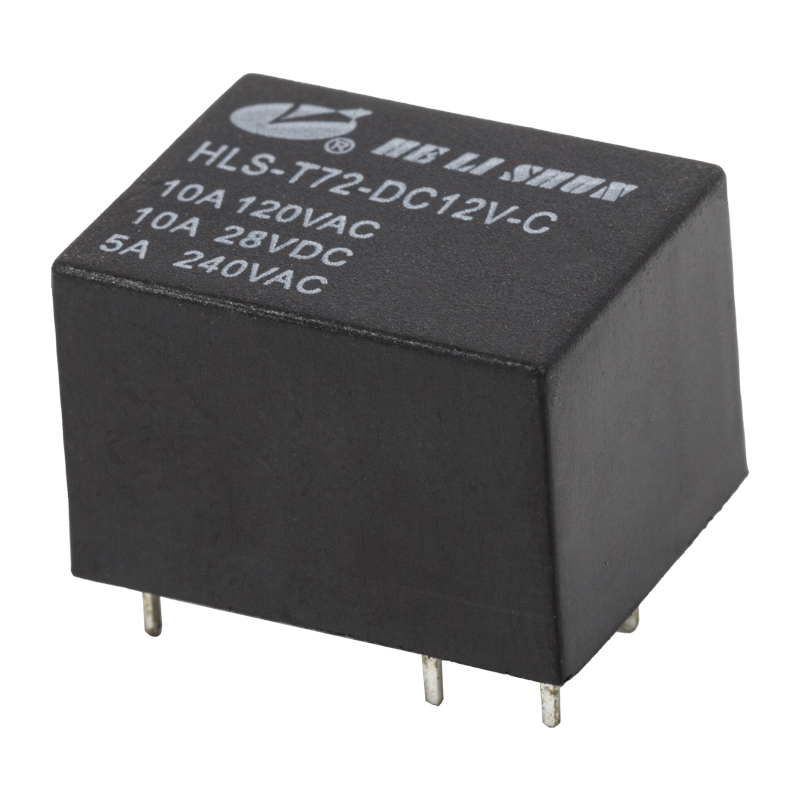

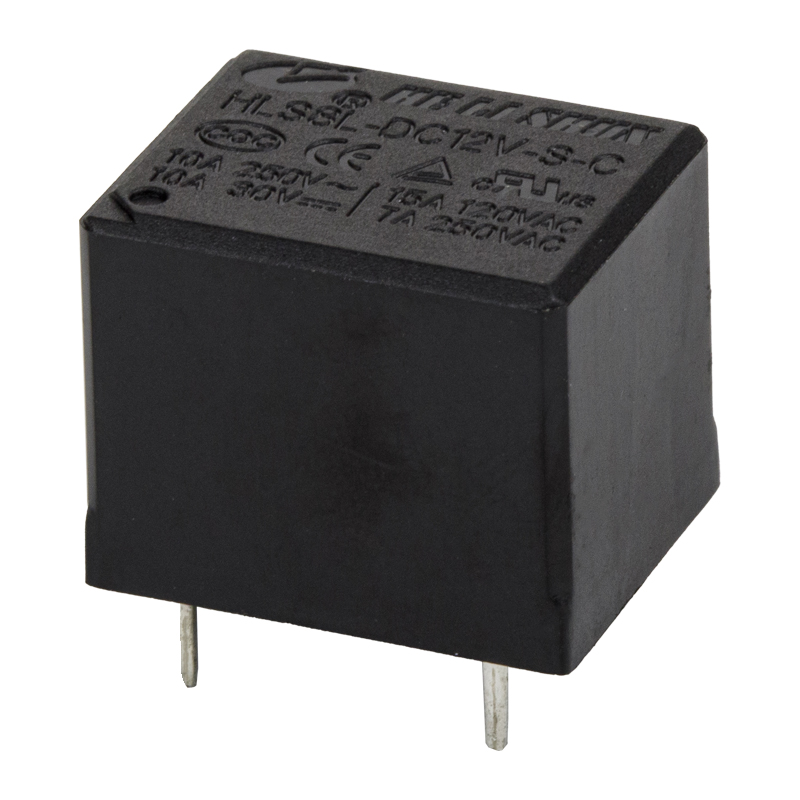

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体