In a high-humidity environment, moisture in the air easily condenses on the surface of the high power relay contact to form a thin layer of water film. This layer of water film not only reduces the conductivity of the contact, but also may cause electrochemical corrosion, resulting in oxidation and rust on the contact surface. Contact corrosion can lead to poor contact of the contact, affecting the electrical connection of the relay, which may cause circuit failure or failure. In addition, the water film on the contact surface may also become a conductive path, causing the relay to malfunction when it should not operate, or fail to operate when it should operate.

The insulating materials inside the relay (such as plastic, rubber, etc.) easily absorb moisture in a high-humidity environment, resulting in a decrease in insulation resistance. The decrease in insulation performance increases the risk of leakage, short circuit and other faults inside the relay, and may even cause serious electrical accidents. In a high-humidity environment for a long time, the insulating material may also undergo physical deformation or aging, further reducing its insulation performance.

A high-humidity environment accelerates the corrosion and oxidation process of metal components inside the relay (such as contacts, coils, etc.). Corrosion and oxidation can cause the performance of metal components to deteriorate, such as electrical conductivity and mechanical strength, thus affecting the overall performance and service life of the relay. In addition, high humidity environments may also cause aging and failure of other non-metallic components inside the relay (such as seals, lubricants, etc.).

Due to the influence of the above factors, the relay may have unstable performance in a high humidity environment. This is manifested in problems such as extended relay action time, shortened release time, insensitive action or malfunction. Unstable performance will reduce the reliability of the relay and bring potential risks to the normal operation of the circuit system.

High humidity environments may cause short circuits, leakage and other faults in the internal circuit of the relay, thereby causing safety hazards such as fire and electric shock. Especially in some application scenarios with high safety requirements (such as industrial automation, medical equipment and other fields), the high humidity sensitivity of the relay may bring serious safety problems.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / If the ambient humidity exceeds 85% relative humidity, what problems may occur with this high power relay?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsIf the ambient humidity exceeds 85% relative humidity, what problems may occur with this high power relay?

Posted by Admin | 17 Jan

PREV:In addition to shock resistance and environmental humidity, what other environmental factors may affect the performance of this 1C 16A 20A power relay?

NEXT:As a contact material, what role does silver alloy play in this 16A power relay?

NEXT:As a contact material, what role does silver alloy play in this 16A power relay?

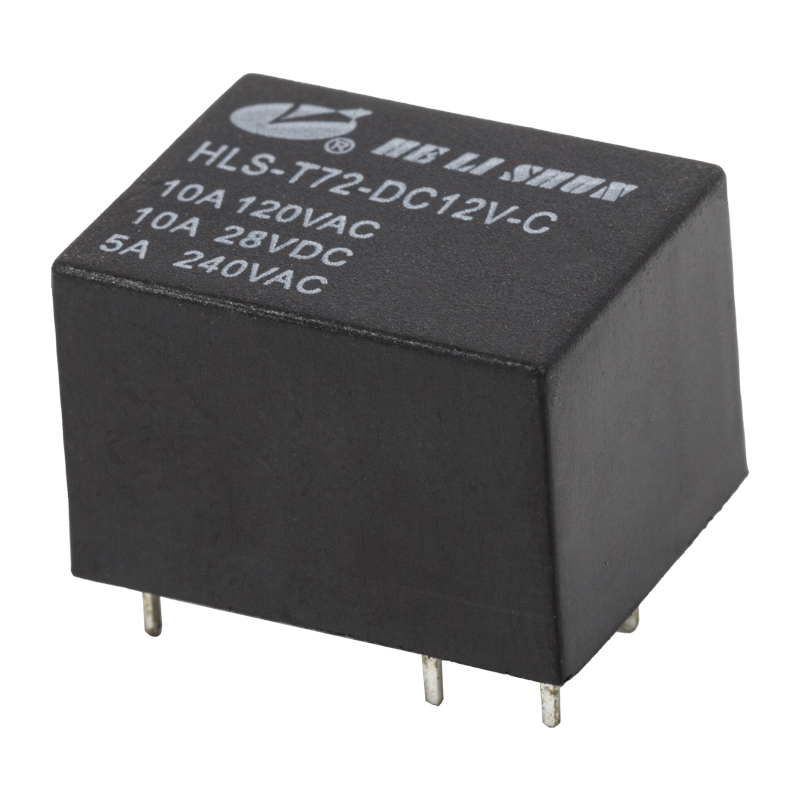

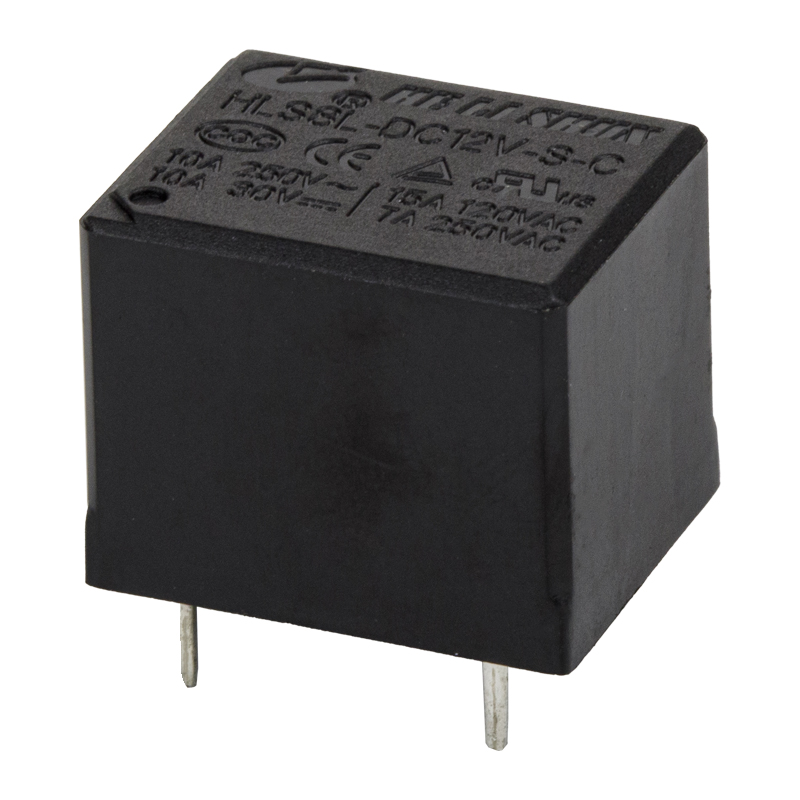

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体