Silver is one of the best conductive metals in nature, and silver alloy can improve the hardness and wear resistance of the material while maintaining high conductivity through alloying with other metal elements. In the 16A power relay, when subjected to large currents, the contacts can quickly and unimpededly transfer electrical energy, reducing heat loss caused by excessive resistance and improving energy efficiency. In addition, good conductivity can also ensure that the voltage drop of the relay is maintained at a low level when the switch is in action, protecting other components in the circuit from damage.

During the frequent opening and closing process, the relay contacts will be subjected to the dual test of mechanical friction and chemical corrosion. Silver alloy contacts have high hardness and strong wear resistance. Even under long-term and high-frequency operation, they can maintain the smoothness of the contact surface and the stability of the contact area, reducing the problem of poor contact caused by wear. At the same time, silver alloy has good corrosion resistance to most environmental media, and can effectively resist the erosion of oxygen, moisture and certain corrosive gases in the air, extending the service life of the contacts.

At the moment of circuit switching, arc discharge may occur between contacts due to the rapid change of current. The arc will not only cause the rapid evaporation of the contact material, but may also cause a short circuit or damage surrounding components. Silver alloy contacts, due to their high thermal conductivity, good thermal stability and non-oxidation characteristics, can effectively resist the high temperature impact of the arc, reduce the duration and intensity of the arc, thereby protecting the contacts from damage and improving the electrical life of the relay.

Silver alloy contacts can still maintain stable contact resistance after multiple opening and closing cycles, which is crucial to ensure the long-term stable operation of the circuit. Stable contact resistance means that the relay will not cause changes in circuit parameters due to contact aging or contamination during long-term operation, thereby ensuring the reliability and consistency of the entire circuit system.

Given the shock resistance (10-55Hz, 1.5mm double amplitude) and environmental humidity adaptability (20-85% relative humidity) of the relay design, silver alloy contacts can also maintain good performance under these extreme conditions. Its weather resistance and moisture resistance ensure that the relay can still work stably in a changing working environment, broadening the application scenarios of the relay.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / As a contact material, what role does silver alloy play in this 16A power relay?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsAs a contact material, what role does silver alloy play in this 16A power relay?

Posted by Admin | 10 Jan

PREV:If the ambient humidity exceeds 85% relative humidity, what problems may occur with this high power relay?

NEXT:What is the main difference between a relay socket and an ordinary socket?

NEXT:What is the main difference between a relay socket and an ordinary socket?

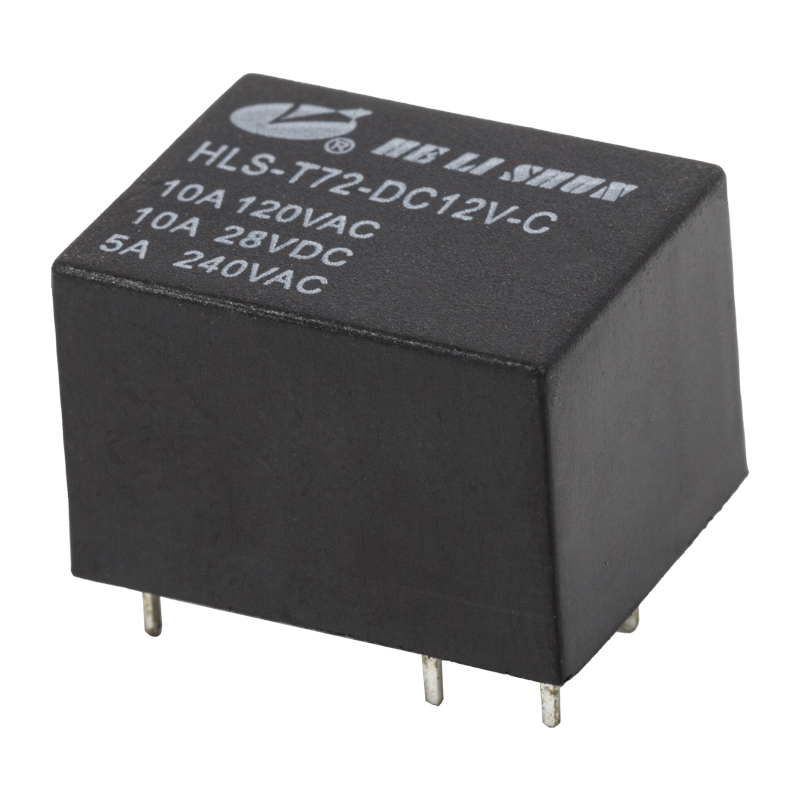

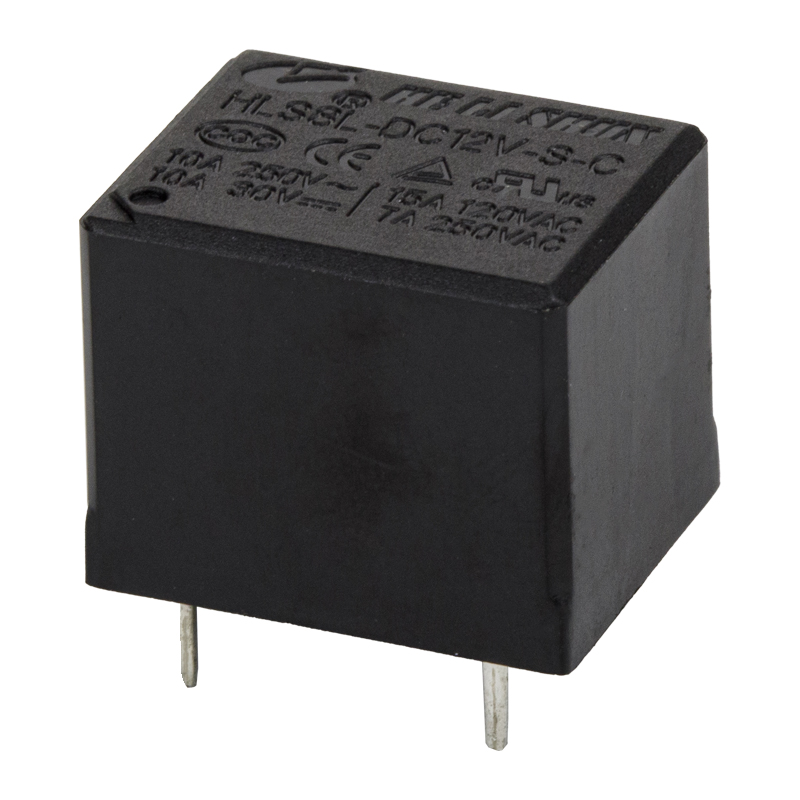

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体