The selection of silver alloy as the contact material for relays is mainly based on the following considerations:

High conductivity: Silver alloy has high conductivity, which can effectively transmit current and reduce energy loss. For electrical components such as relays that need to transmit current frequently, high conductivity contact materials can ensure stable current transmission and improve the performance of relays.

Good arc breaking performance: Relays may generate arcs during the switching process, which can damage the contact materials. Silver alloy has good arc breaking performance, which can quickly extinguish the arc and reduce the erosion of the arc on the contacts, thereby extending the service life of the relay.

High resistance to fusion welding: Under high-frequency or high-load working conditions, fusion welding may occur between the relay contacts due to excessive current, insufficient contact pressure or improper selection of contact materials. Fusion welding not only causes relay failure, but also may damage the circuit system. As an excellent contact material, silver alloy has high resistance to fusion welding. This is mainly due to the high melting point of silver alloy. At the same time, its alloy composition can improve the physical properties of the material, so that the contacts can quickly disconnect the current when separated, reducing the occurrence of welding. Therefore, in high-frequency or high-load application scenarios, choosing silver alloy as the contact material of the relay can significantly improve the stability and reliability of the relay.

Lower surface contact resistance: Contact resistance refers to the resistance generated by the uneven surface, oxidation, pollution, etc. of the contact when the current passes through the contact. The size of the contact resistance directly affects the performance of the relay, including current transmission efficiency, temperature rise, etc. As a high-quality conductive material, silver alloy has a low surface contact resistance. This is mainly due to the high conductivity and good processing performance of silver alloy. Through fine processing and surface treatment, the contact resistance of silver alloy contacts can be further reduced and the performance of the relay can be improved. Lower surface contact resistance can reduce the energy loss of current during transmission, reduce the temperature rise of the relay, and improve the efficiency and life of the relay.

Strong wear resistance: During the use of the relay, the contacts will constantly contact and separate, which will cause wear on the contact surface. Wear will reduce the contact performance of the contacts, leading to problems such as poor contact and increased contact resistance, thereby affecting the performance and reliability of the relay. As a material with strong wear resistance, silver alloy can resist this kind of wear to a certain extent. This is mainly due to the moderate hardness, good toughness and strong corrosion resistance of silver alloy. At the same time, the alloy composition of silver alloy can also improve its wear resistance, making it have better wear resistance. Therefore, choosing silver alloy as the contact material of the relay can reduce problems such as poor contact caused by wear and improve the reliability and stability of the relay. In practical applications, it is also necessary to pay attention to regular maintenance and care of the relay to extend its service life and improve its performance.

Good conductivity: Silver alloy has good conductivity and can play a good role in low-voltage, low-current and low-power switching applications. For this product, its maximum switching voltage is 250 volts AC/30 volts DC, and the maximum switching current is 10A. Silver alloy contacts can meet these requirements and ensure the normal operation of the relay.

In summary, silver alloy has many advantages as the contact material used in relays, which can meet the performance requirements of relays and improve the reliability and stability of relays. At the same time, silver alloy contacts are also widely used in small-capacity low-voltage electrical appliances, such as relays, timers, auxiliary switches, household appliance switches, control switches, etc.

Web Menu

Product Search

Exit Menu

news

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhy choose silver alloy as the contact material for relays?

Posted by Admin | 17 Jun

PREV:How to ensure that the automotive relay does not exceed its maximum switching current and voltage limits during use?

NEXT:Why are silver and gold chosen as the contact materials for this telecom relay?

NEXT:Why are silver and gold chosen as the contact materials for this telecom relay?

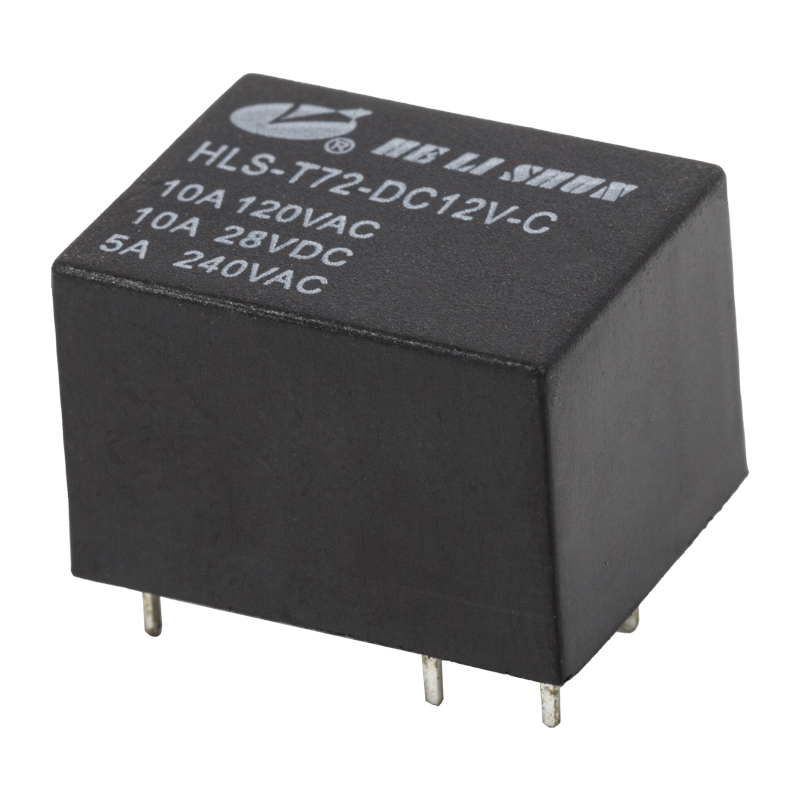

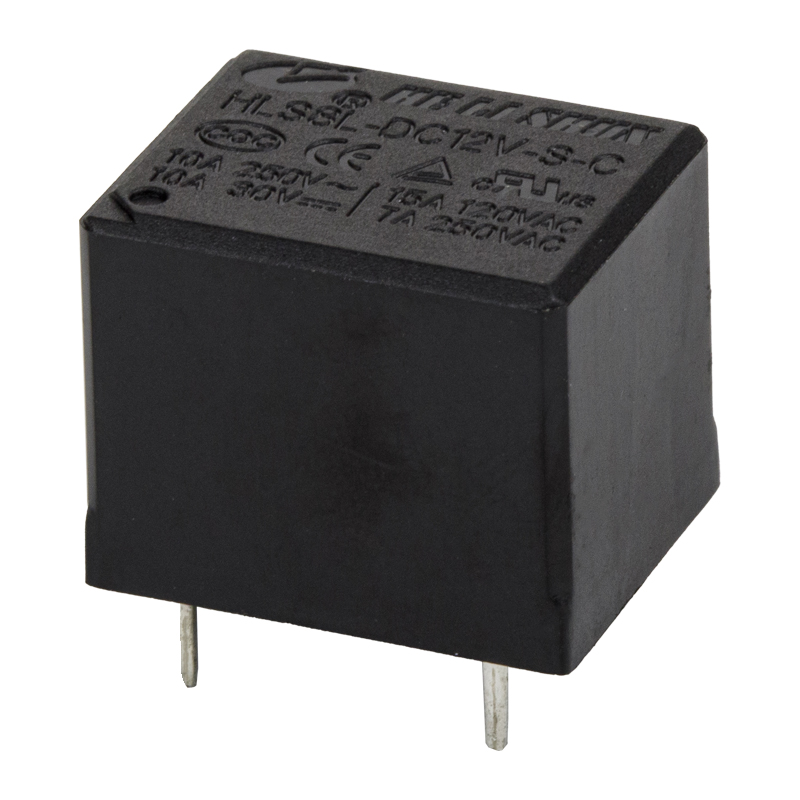

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体