The socket interface, as the most widely used interface type in the field of relay sockets, is particularly suitable for the connection needs of relays on circuit boards. The following will elaborate on the socket interface in detail from multiple aspects such as structural design, plug-in convenience, electrical performance, applicability, safety and application scenarios.

The structural design of the socket interface is its core. The socket body is usually made of high-quality insulating materials such as plastic or ceramic to ensure electrical isolation and safety. These materials not only have good insulation properties, but also maintain stability in high temperature and humid environments. There are multiple sockets on the socket body corresponding to the relay pins. The shape, size and arrangement of the sockets are precisely designed to ensure that the relay pins can be inserted accurately and form a reliable electrical connection. Metal spring sheets or gold-plated contacts are usually provided inside the socket to enhance the tightness and conductivity of the contact.

The biggest advantage of the socket interface is its plug-in convenience. The relay can be connected to the socket body through a simple insertion action without complicated welding or screw fixing process. Similarly, when the relay needs to be replaced, it can be pulled out gently without the need for additional disassembly tools. This design not only simplifies the installation process and improves work efficiency, but also enables the rapid replacement of relays during maintenance and repair, reducing downtime.

The socket interface performs well in electrical performance. The contact area between the jack and the pin is large and the contact is close, thus ensuring good conductivity. In addition, the socket interface usually has a certain degree of anti-vibration and anti-interference ability, and can maintain a stable electrical connection in a harsh working environment. This stability is essential to ensure the normal operation of the circuit and extend the service life of the relay.

The socket interface has a wide range of applicability. It can be used with relays of various types and specifications, including electromagnetic relays, solid-state relays, etc. At the same time, it can also be used with different types of circuit boards, such as DIP (dual in-line package) circuit boards, plug-in circuit boards, etc. This wide applicability makes the socket interface a mainstream choice among relay sockets, which can meet the needs of different industries and fields.

The socket interface also performs well in safety. The socket body is usually made of insulating material, which can effectively prevent electrical short circuits and electric shock accidents. In addition, the socket interface also has a certain degree of waterproof and dustproof ability, which can protect the relay from the external environment to a certain extent. These safety measures not only improve the reliability of the product, but also ensure the safety of the operator.

The application scenarios of the socket interface are very wide. It is often used in industrial automation, power control, communication equipment, automotive electronics and other fields. In these fields, relays are usually used to control the on and off of circuits, amplify signals and other key tasks. The existence of the socket interface makes these tasks more convenient and efficient, while improving the reliability and stability of the system.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / What are the safeguards for the safety of the socket interface of the relay socket?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsWhat are the safeguards for the safety of the socket interface of the relay socket?

Posted by Admin | 27 Dec

PREV:What is the main difference between a relay socket and an ordinary socket?

NEXT:In the design of telecom relay, why is gold + silver alloy chosen as the contact material, and how is this related to shock resistance and environmental humidity adaptability?

NEXT:In the design of telecom relay, why is gold + silver alloy chosen as the contact material, and how is this related to shock resistance and environmental humidity adaptability?

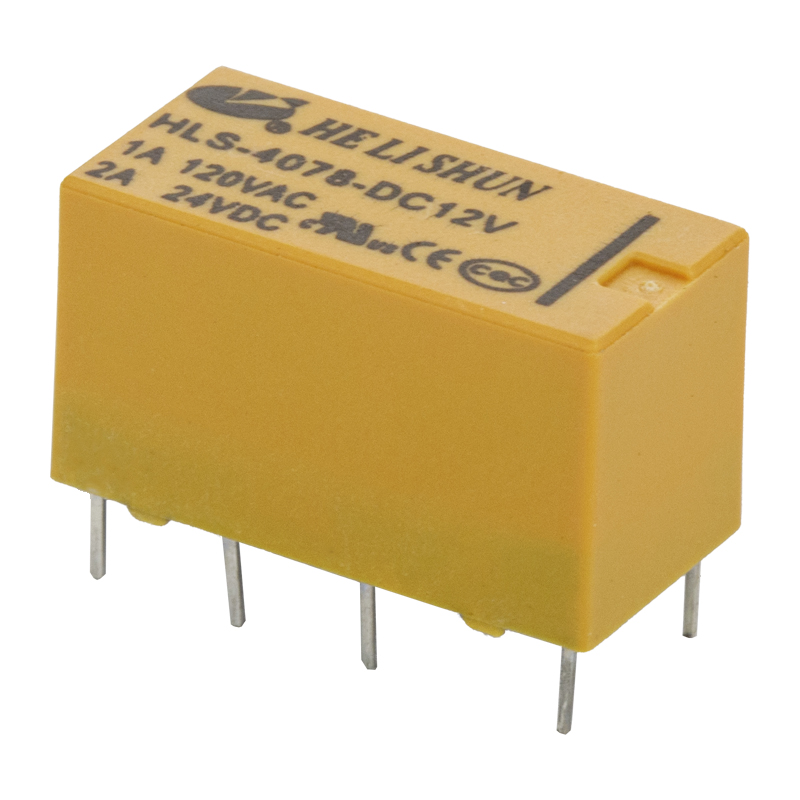

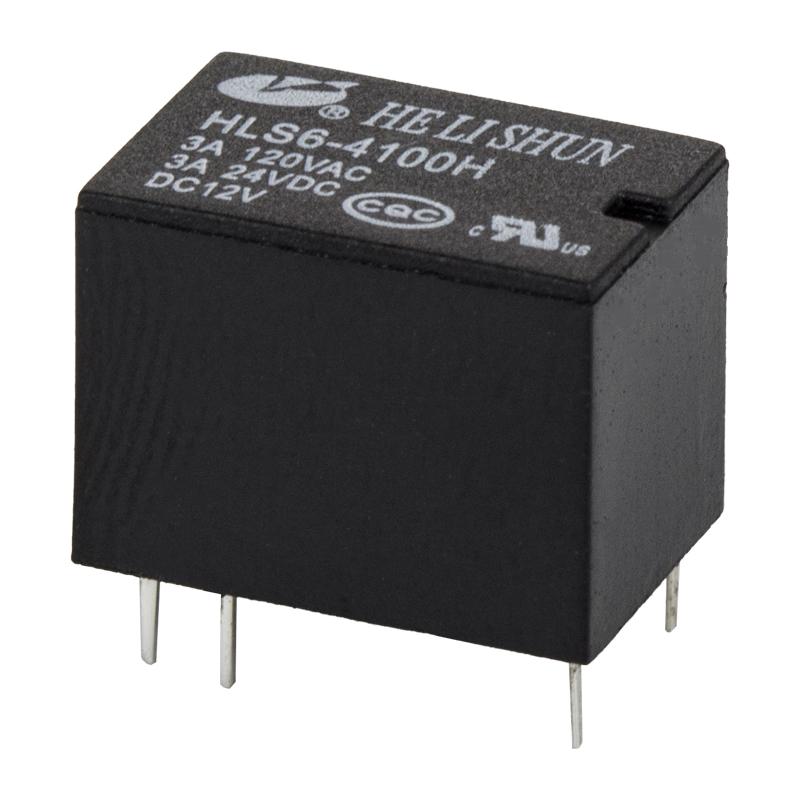

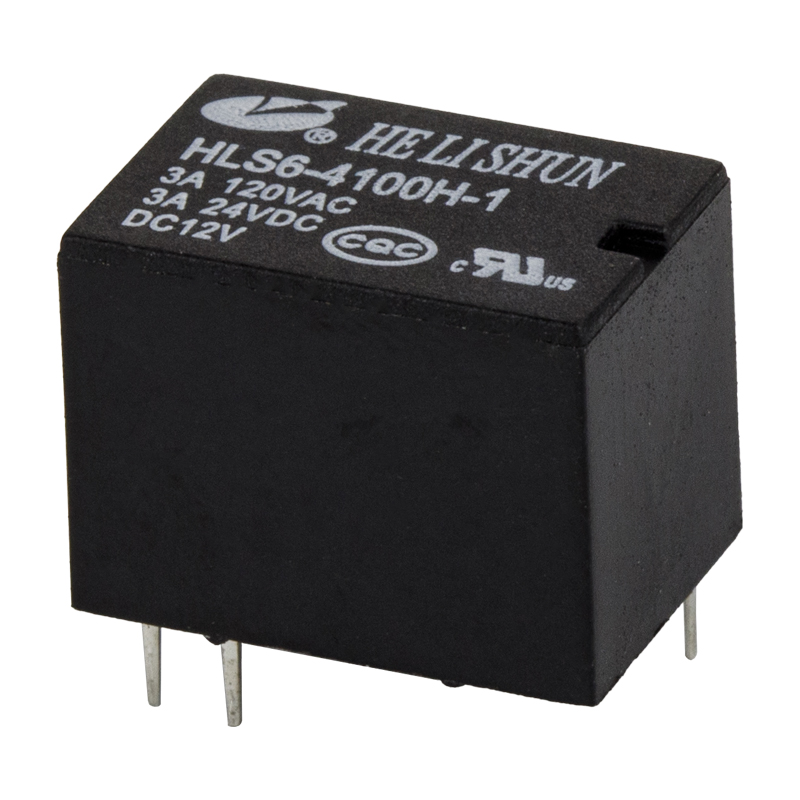

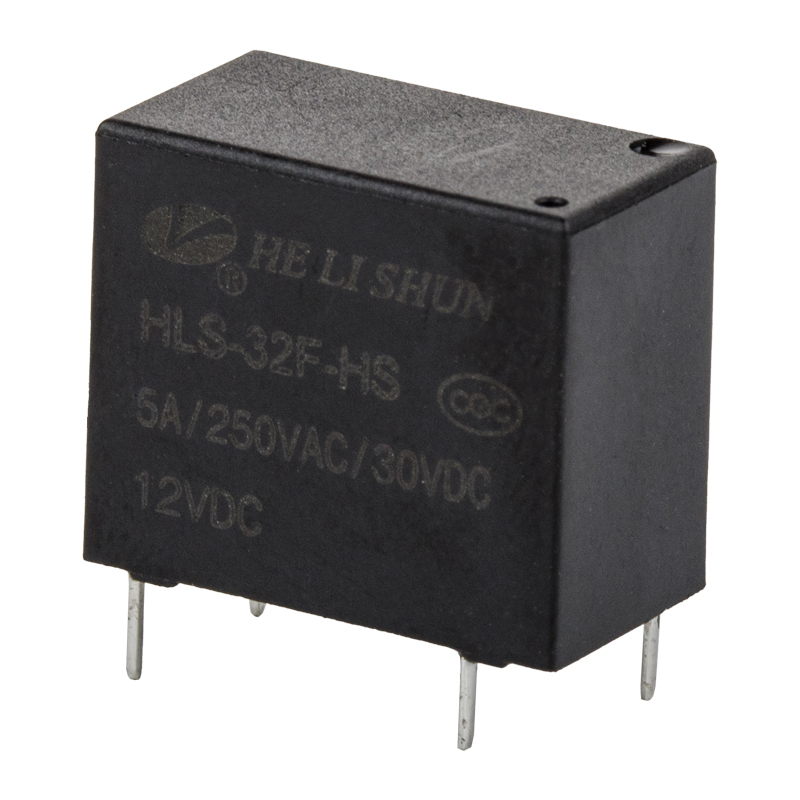

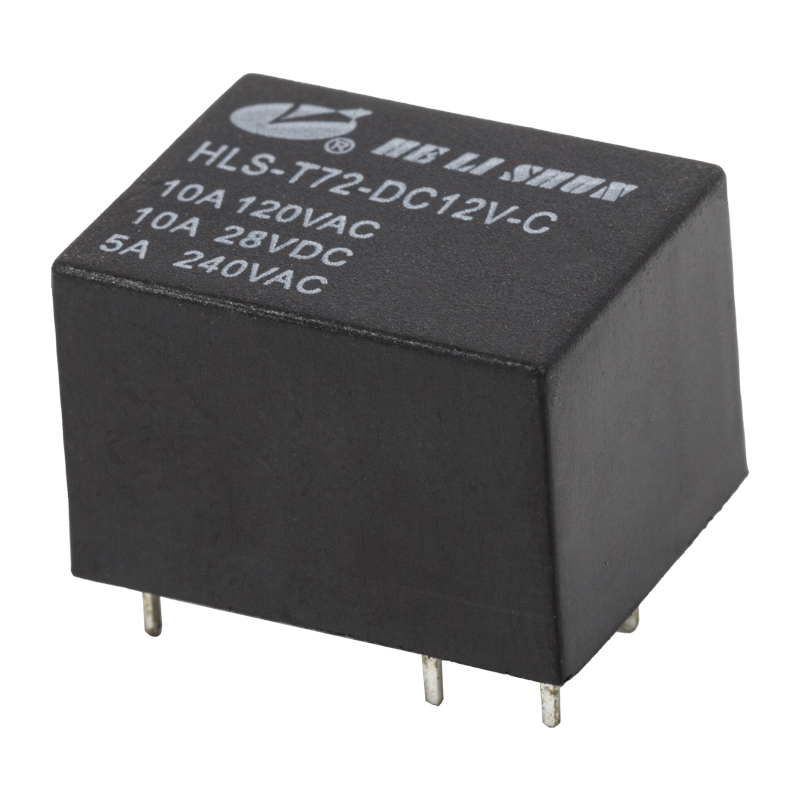

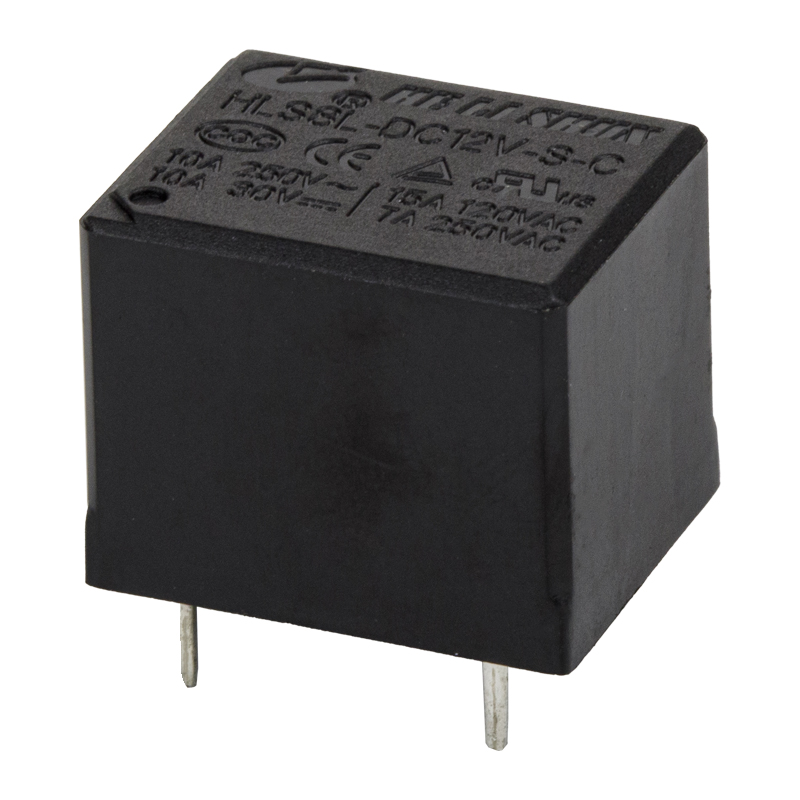

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体