In electronic circuits, PCB Power Relay serves as an important control component and is widely used in various power systems and automation equipment. However, with the continuous development of electronic technology, the requirements for the working stability and reliability of relays are becoming higher and higher. Among them, heat dissipation performance is one of the key factors in the working performance of the relay and has a non-negligible impact on the stability of the circuit.

We need to understand that PCB Power Relay will generate a certain amount of heat when working. This heat mainly comes from the current passing through the relay's internal coil and the contact resistance between the contacts. If the heat dissipation performance is poor, the heat cannot be dissipated in time, which will cause the temperature inside the relay to rise. Long-term high-temperature operation will not only reduce the electrical performance of the relay, but may also cause aging of the insulating material, melting of the contacts and other faults, thus affecting the normal operation of the circuit.

Secondly, the heat dissipation performance of PCB Power Relay will also affect its working stability. In a high-temperature environment, the operating characteristics of the relay may change, such as extended operating time, shortened release time, etc. These changes may cause the relay to be unable to accurately perform control tasks in the circuit, causing failure of the entire system. In addition, high temperatures may accelerate the aging of the internal components of the relay, shorten its service life, and increase maintenance costs.

Therefore, optimizing the heat dissipation performance of PCB Power Relay is of great significance to improve circuit stability. When designing relays, manufacturers should fully consider heat dissipation issues and adopt reasonable heat dissipation structures and materials to improve the heat dissipation efficiency of relays. At the same time, users should also pay attention to maintaining a good ventilation environment when using relays, and avoid installing relays in closed or high-temperature environments.

In addition, with the advancement of science and technology, new heat dissipation technologies and materials are constantly emerging, providing new solutions to the heat dissipation problem of PCB Power Relay. For example, the use of heat pipe cooling technology, nano-heat dissipation materials, etc. can further improve the heat dissipation performance of the relay and ensure the stable operation of the circuit.

The heat dissipation performance of PCB Power Relay has an important impact on circuit stability. By optimizing the heat dissipation design and adopting new heat dissipation technologies, the heat dissipation performance of the relay can be effectively improved to ensure the stability and reliability of the circuit.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / The impact of PCB Power Relay’s heat dissipation performance on circuit stability

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsThe impact of PCB Power Relay’s heat dissipation performance on circuit stability

Posted by Admin | 09 May

PREV:The impact of PCB Power Relay life and reliability on circuit systems

NEXT:How are the rated current and voltage parameters of High Power Relay determined?

NEXT:How are the rated current and voltage parameters of High Power Relay determined?

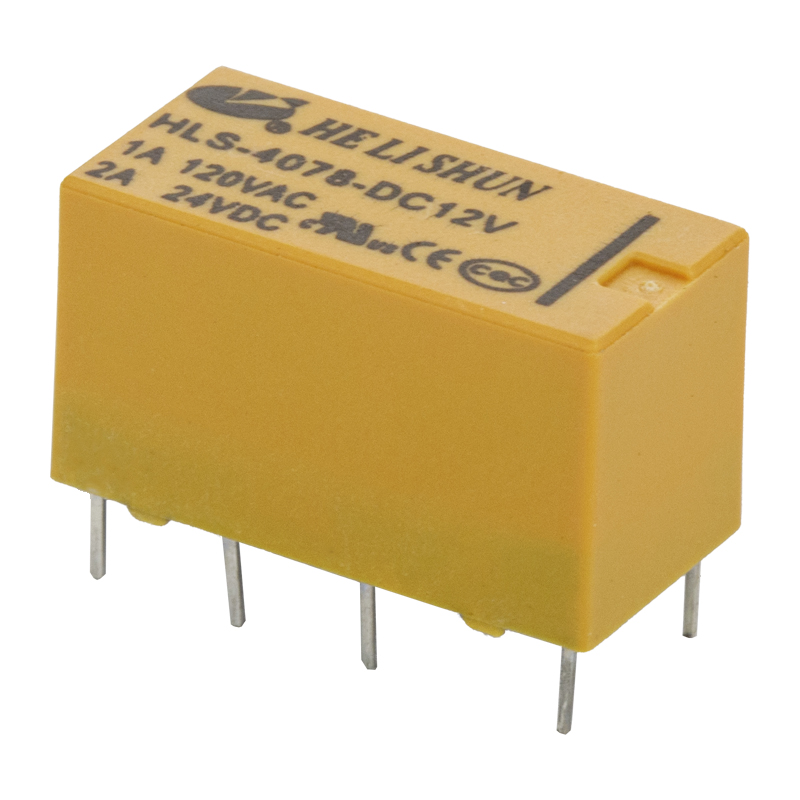

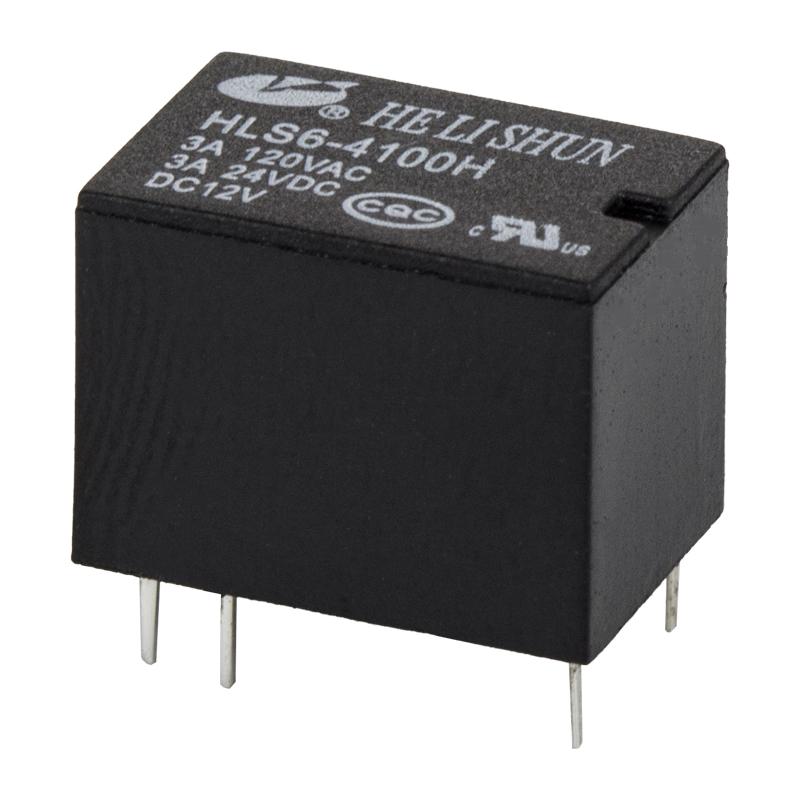

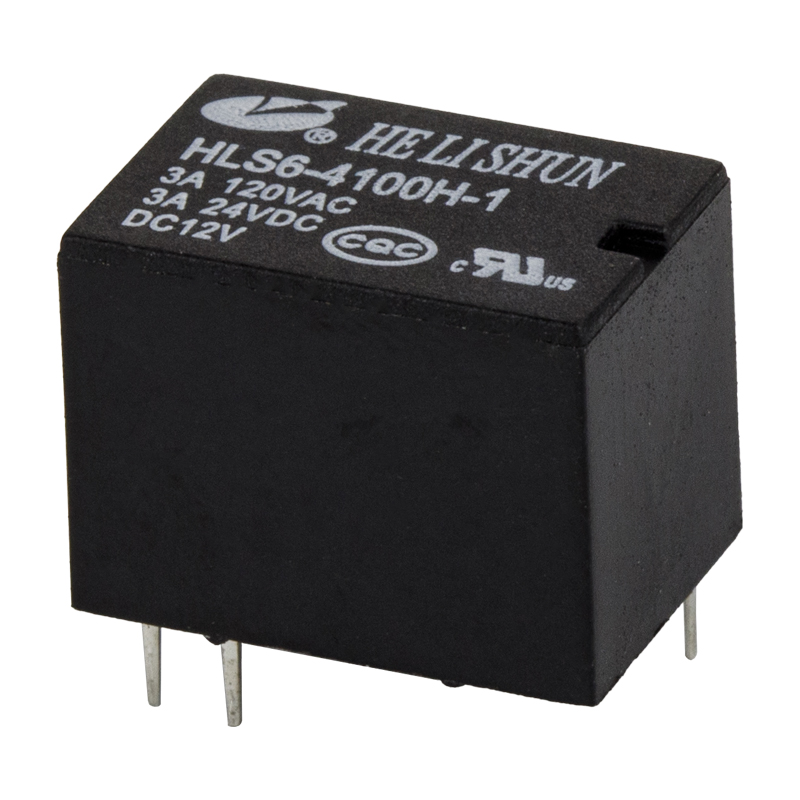

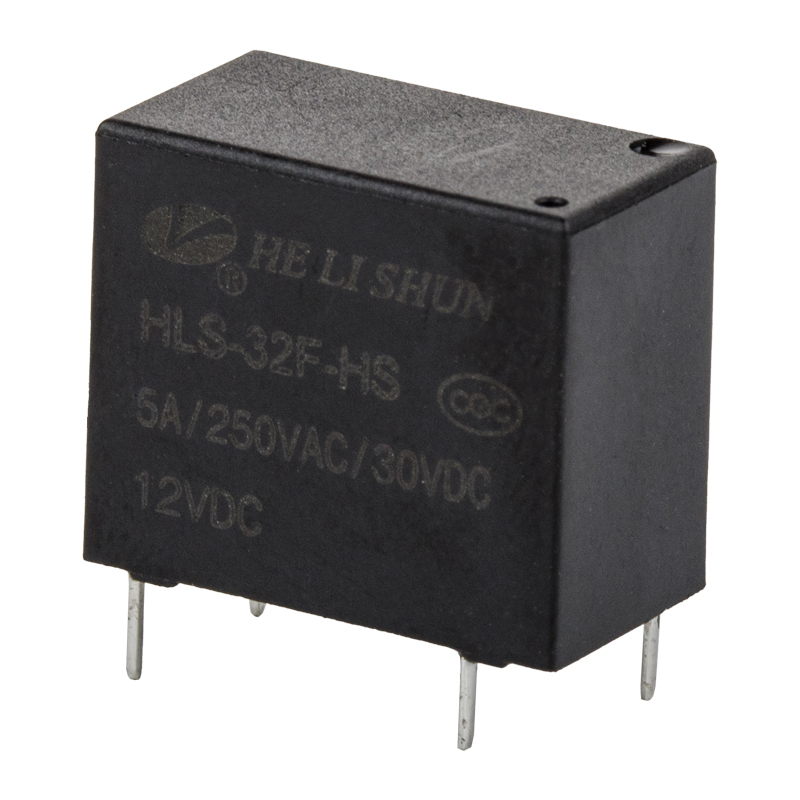

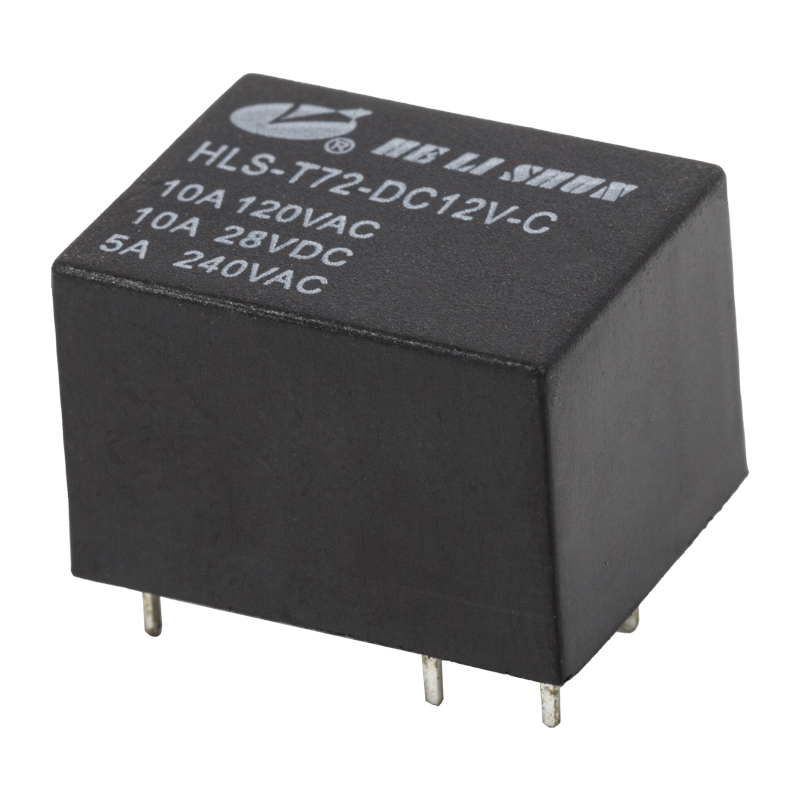

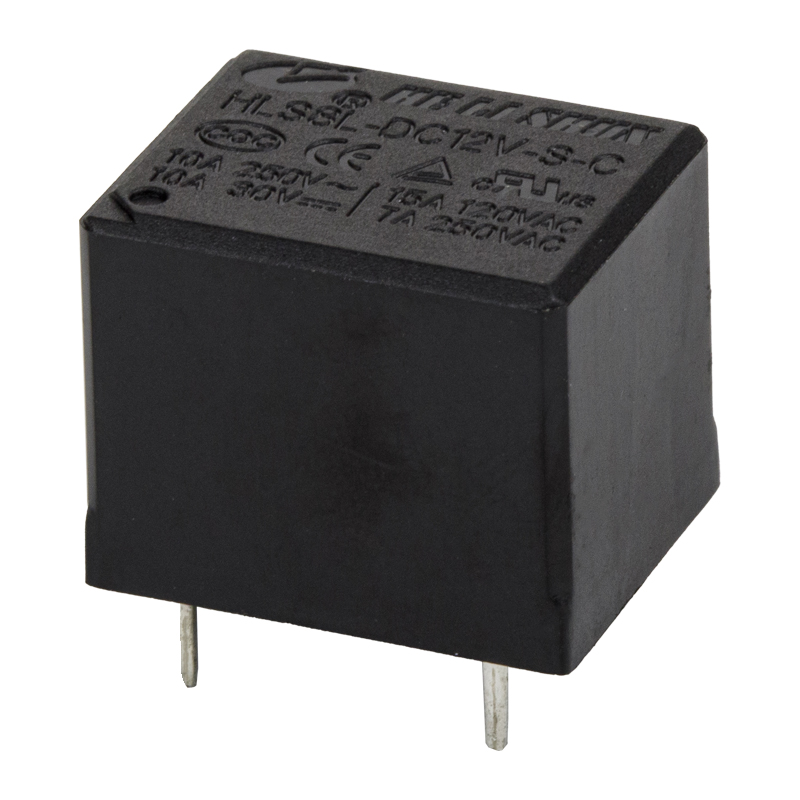

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体