In terms of technical parameters and performance matching, the antumotive relay uses silver alloy contacts, which have excellent conductivity and arc erosion resistance, and can adapt to the needs of high-frequency switching of high-voltage current in motor control systems. Its operation time and release time can quickly respond to motor control signals and meet real-time requirements. However, new energy vehicle motor controllers usually involve high-voltage DC, and it is necessary to focus on confirming whether the relay has passed the high-voltage insulation certification to ensure safe and stable operation in the vehicle-mounted high-voltage environment. If there is a lack of relevant certification, its electrical performance may not fully match the stringent requirements of new energy vehicle motor control.

Environmental adaptability and reliability verification are key considerations for vehicle-mounted equipment. The nominal ambient temperature range of the relay covers the extreme working conditions of new energy vehicles, but its performance stability under temperature cycle shock needs to be further verified. The humidity range (40-85% RH) requires a sealed design to avoid the risk of short circuit caused by contact condensation; if it does not reach the IP67 waterproof level, there may be hidden dangers in wading or high humidity environments. The vibration resistance (20-200Hz, 1.5mm double amplitude) meets the automotive vibration standards (such as ISO 16750), but targeted testing is required in combination with the installation location to ensure long-term reliability.

Industry certification and functional safety are hard thresholds for new energy vehicle components. If the relay does not pass the AEC-Q series certification, it will be difficult to meet the reliability requirements of the Automotive Electronics Council for passive components. In addition, relays involving motor control must support the ISO 26262 functional safety standard and provide ASIL level compliance documents to ensure driving safety in fault mode.

If the relay is not designed for the on-board high-voltage system, it may cause arcing or breakdown risks due to insufficient insulation. It is recommended to choose a model designed specifically for electric vehicles (such as enhanced arc extinguishing structure, wide creepage distance design). In terms of life, new energy vehicles require the life of key components to be ≥10 years or one million operations, and the durability test data of the relay under on-board load needs to be verified. Electromagnetic compatibility (EMC) is also critical. High-frequency switching of motors is prone to interference. It is necessary to confirm whether the relay complies with automotive EMC standards such as CISPR 25 to avoid affecting the stability of the vehicle's electronic system.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / Is this antumotive relay suitable for new energy vehicle motor control?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsIs this antumotive relay suitable for new energy vehicle motor control?

Posted by Admin | 21 Mar

PREV:How do relay sockets and relays work together?

NEXT:What are the typical application scenarios of automotive relays in automotive electrical systems?

NEXT:What are the typical application scenarios of automotive relays in automotive electrical systems?

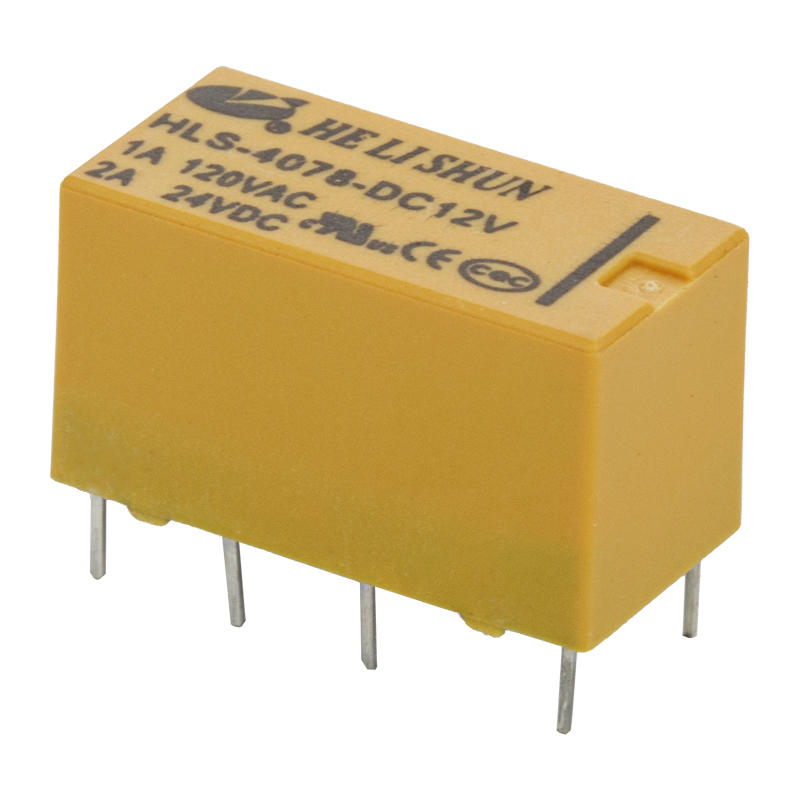

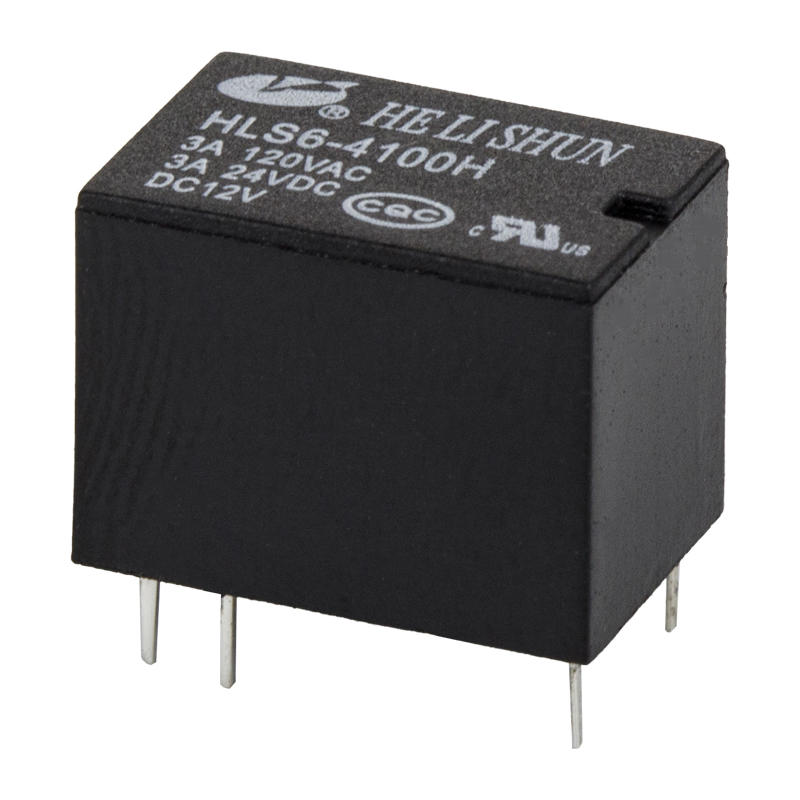

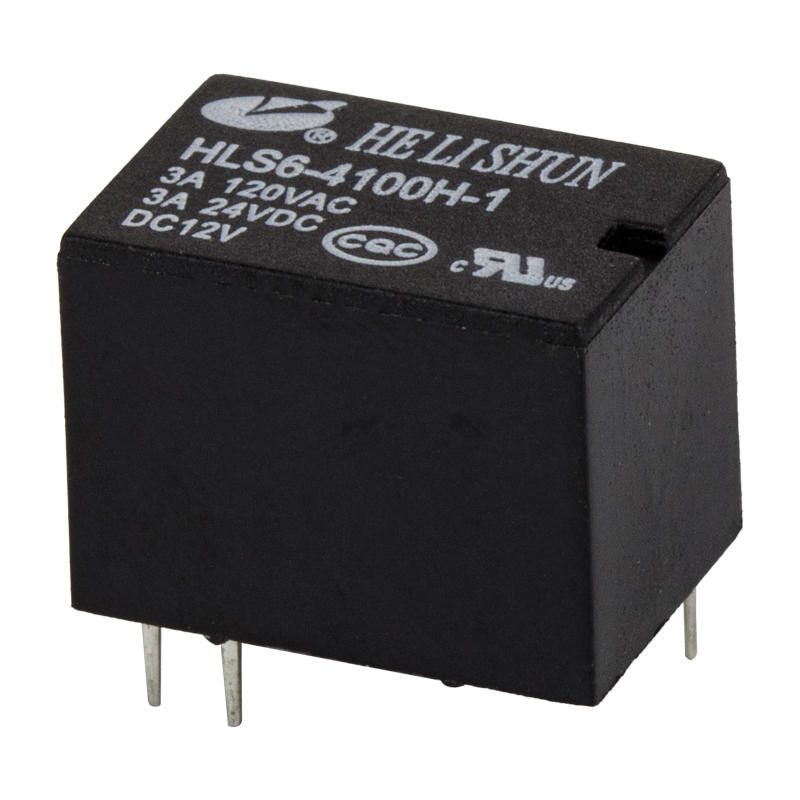

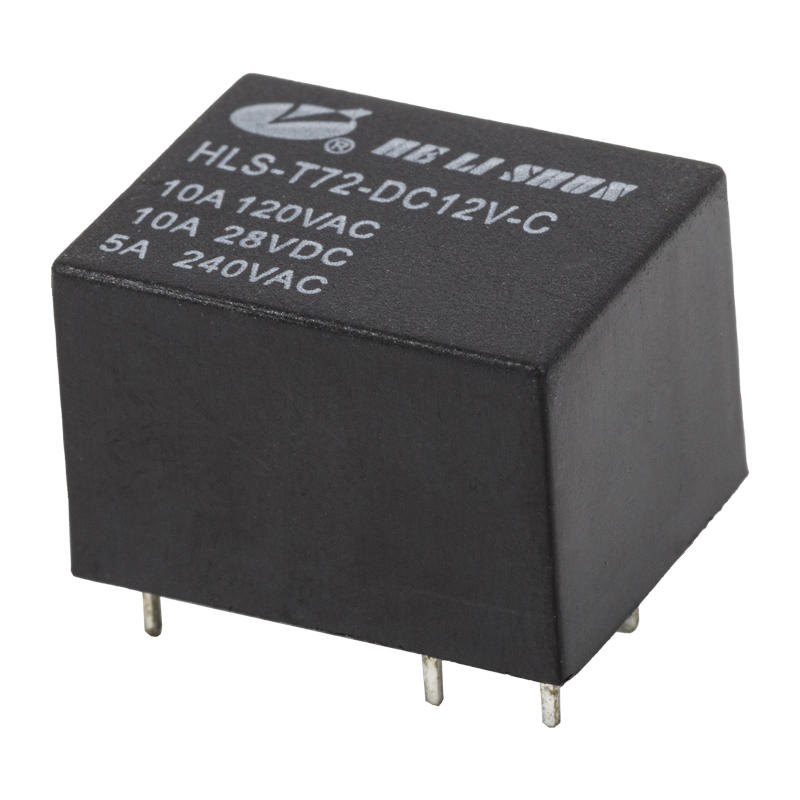

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright © Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体