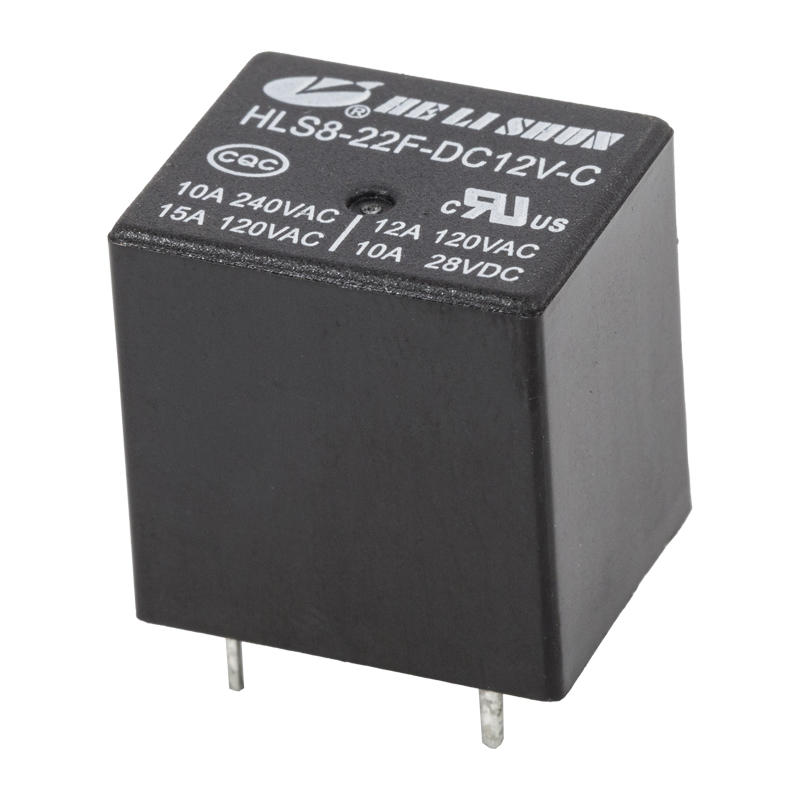

DPDT (Double Pole Double Throw) power relay, that is, double pole double throw power relay, plays an important role in power control and automation systems. Due to its high reliability and wide applicability, DPDT power relay is widely used in a variety of applications. However, in order to ensure the stable operation of the system, it is particularly important to regularly detect whether the working status of the DPDT power relay is normal.

1. Appearance inspection

First, perform a visual inspection. Check the relay housing for damage or cracks and the terminals for looseness or corrosion. Also, check for unusual heat buildup or a burning smell around the relay, which may be signs of internal relay failure.

2. Coil resistance measurement

Use a multimeter to measure the resistance value of the DPDT power relay coil. In the specification book of the relay, the standard value of the coil resistance is usually given. Compare the actual measured value with the standard value. If the deviation is too large, it may indicate a fault in the coil.

3. Contact status check

Without power, manually operate the operating mechanism of the relay to check whether the contacts can switch normally. Ensure that the normally open contact is in the open state and the normally closed contact is in the closed state when the relay is not in action; when the relay is in action, the contact state should be reversed.

4. Power on test

Energize the relay and observe its operation. In the power-on state, use a multimeter or oscilloscope to detect the voltage or current signal of the contact to ensure that the signal changes normally when the contact switches. At the same time, pay attention to whether there are any abnormal sounds when the relay is operating. This may be a sign of poor contact or loose mechanical structure.

5. Load test

In the actual working environment, the relay is connected to the circuit for load testing. By observing and recording the operation of the relay and the working status of the load circuit, determine whether the relay can work normally.

6. Temperature test

During the load test, use an infrared thermometer or contact thermometer to check the temperature of the relay. If the temperature of the relay is too high during operation, it may indicate an internal fault or poor heat dissipation.

Through the detection of the above steps, you can initially judge whether the working status of the DPDT power relay is normal. However, it should be noted that these tests are only preliminary screening methods. For some complex faults, more professional testing equipment and more in-depth investigation may be required. Therefore, in practical applications, it is recommended to develop a more detailed and comprehensive detection plan based on the specific system environment and operating requirements. At the same time, regular maintenance and upkeep of the relay is also an important measure to ensure its long-term stable operation.

Web Menu

Product Search

Exit Menu

news

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsHow to check whether the working status of DPDT Power Relay is normal

Posted by Admin | 19 Apr

PREV:Combined application of Telecom Relay and optical fiber communication technology

NEXT:The intelligent development trend of Socket For Relay

NEXT:The intelligent development trend of Socket For Relay

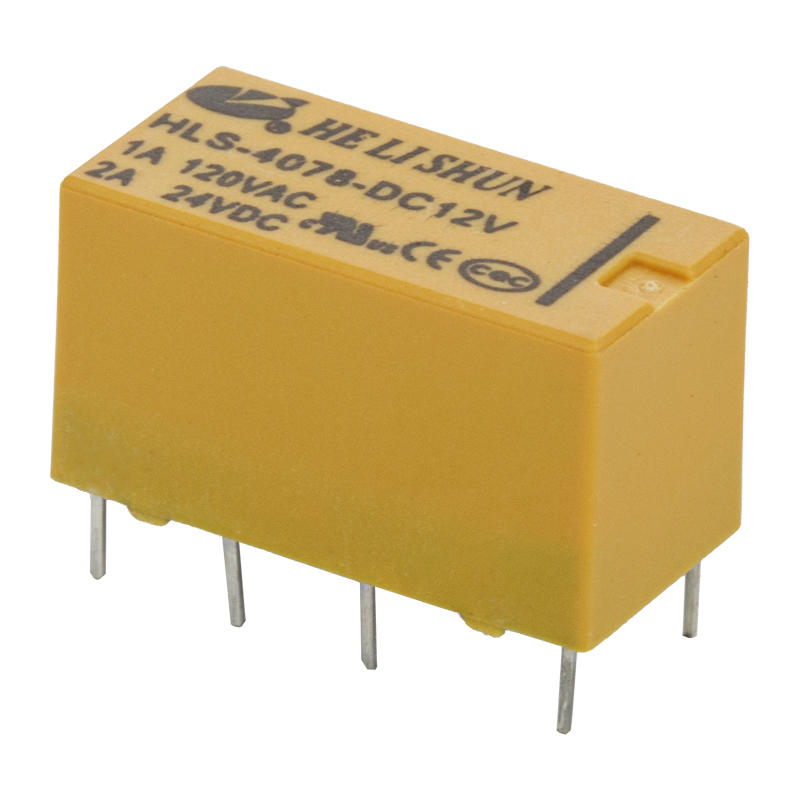

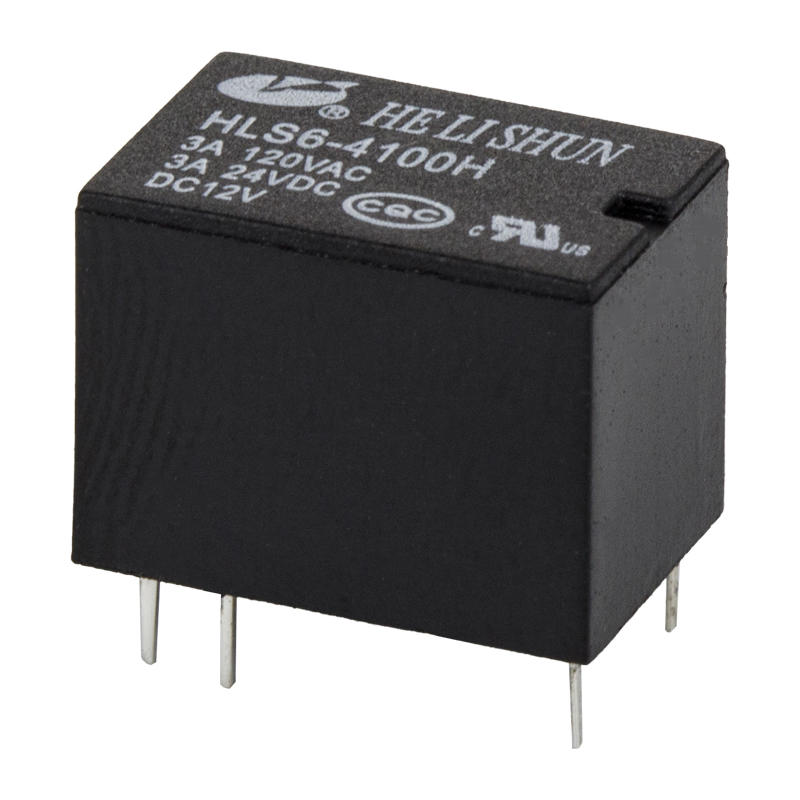

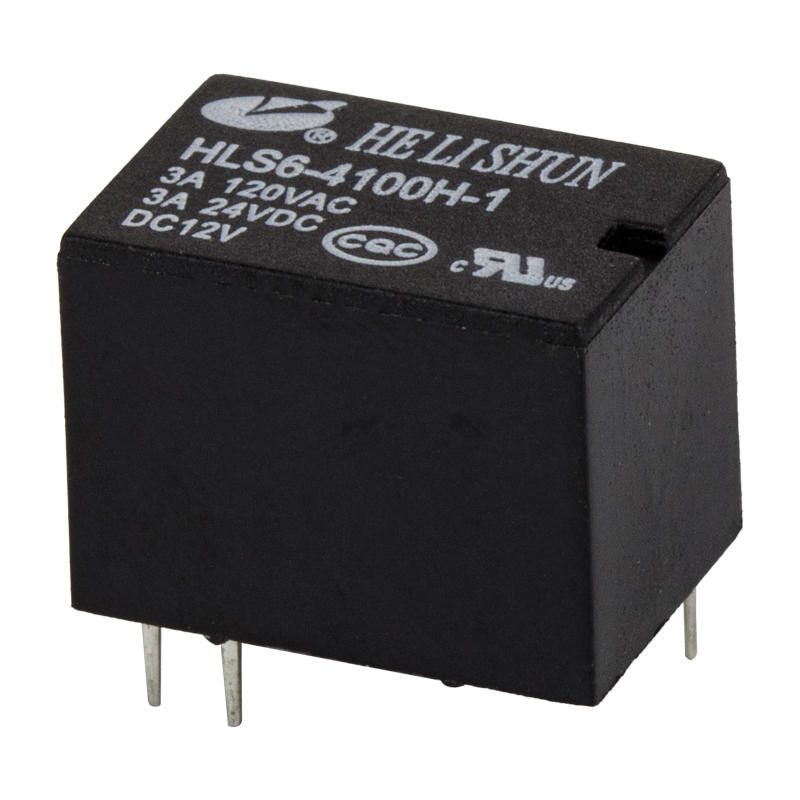

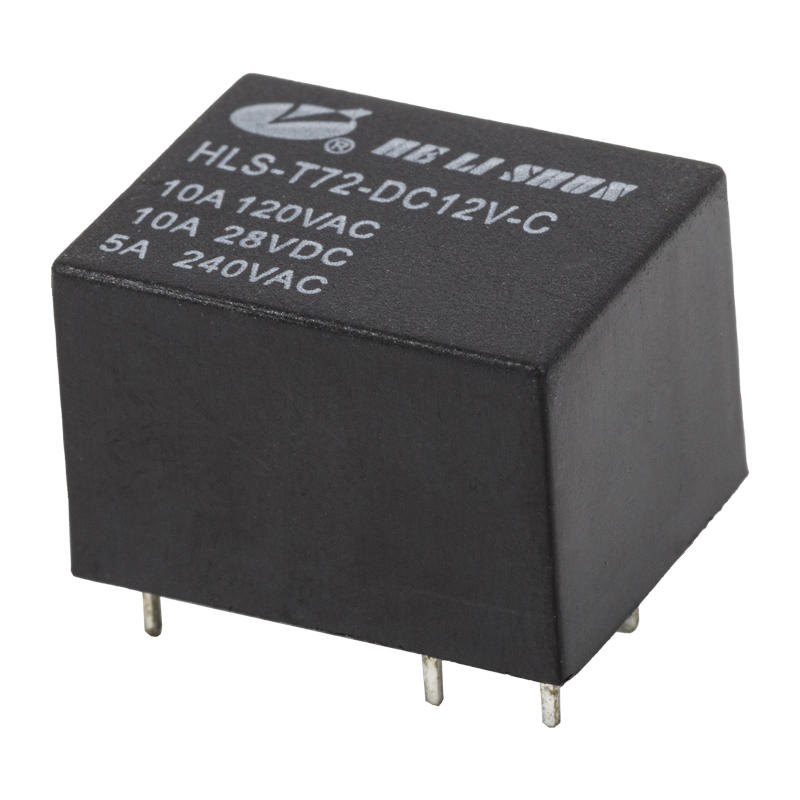

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright © Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体