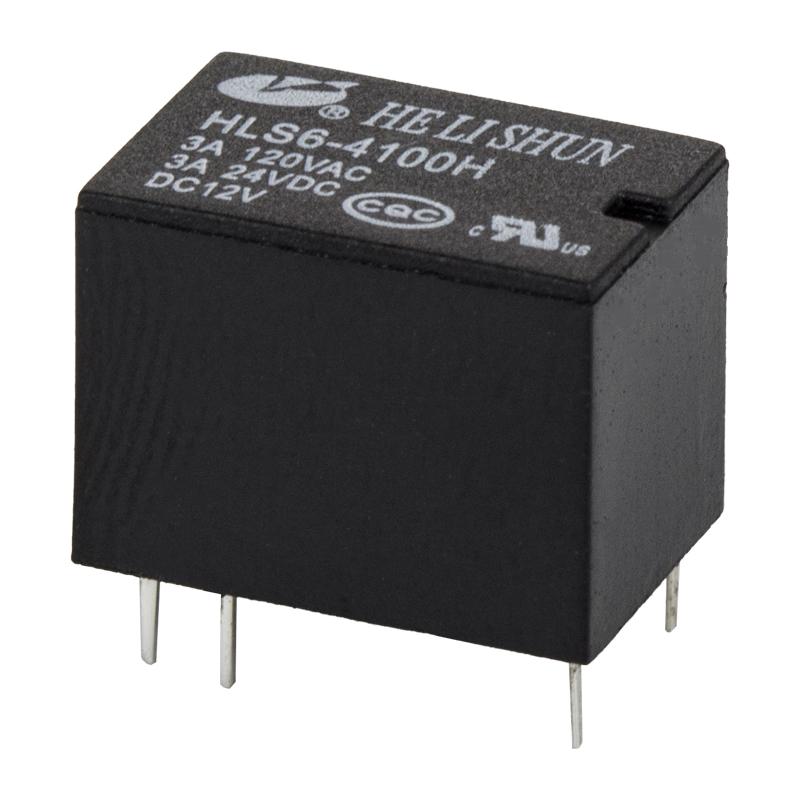

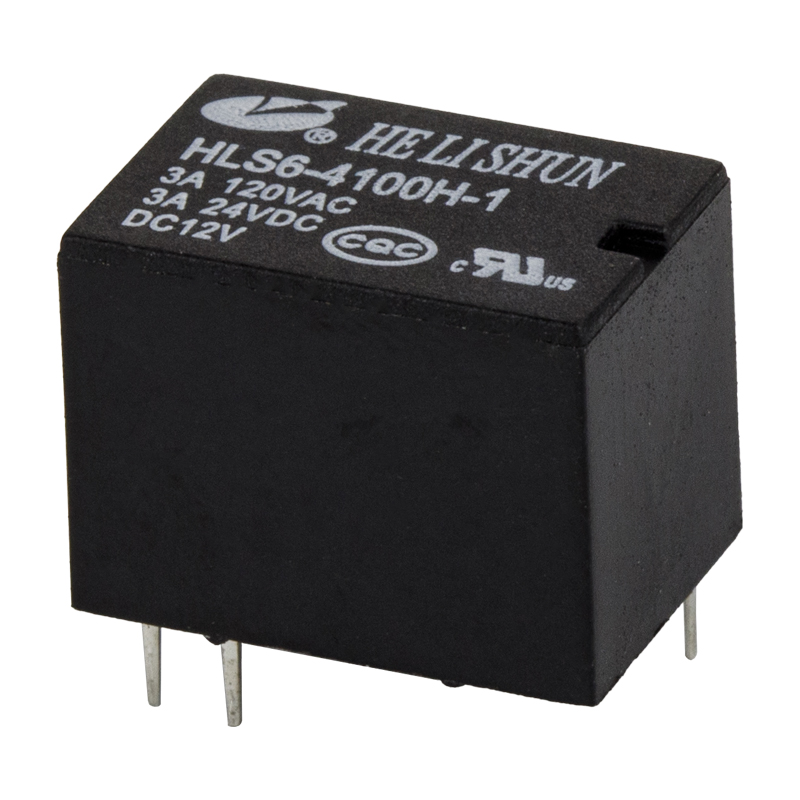

In a high humidity environment, in order to protect the telecom relay PCB PIN HLS6-4100H-1 from corrosion or short circuit, the following specific measures can be taken:

Choose the appropriate waterproof level: When purchasing a relay, you should choose a relay with an appropriate waterproof level according to the actual use environment. For example, a relay with a waterproof level of IP67 or IP68 can prevent water intrusion to a certain extent and is suitable for a high humidity environment.

Add a waterproof cover: Adding a waterproof cover to the relay is a simple and effective protection method. The waterproof cover can effectively prevent the relay from being affected by environmental factors such as water mist and water droplets, and maintain its normal operation. When choosing a waterproof cover, you should ensure that the specifications and models of the cover match the relay to completely cover the relay. The specifications and models of the waterproof cover should match the relay to ensure that the relay can be completely covered and provide effective waterproof protection. The material of the waterproof cover should have good waterproof performance and corrosion resistance, and be able to withstand the erosion of water vapor and chemicals in a high humidity environment. At the same time, the craftsmanship of the waterproof cover should be fine to ensure its sealing performance. The installation of the waterproof cover should be simple and convenient, and it should be easy to maintain and replace. During installation, ensure that the connection between the waterproof cover and the relay is tight and reliable to avoid water leakage.

Use sealant: Sealant can effectively block the erosion of moisture and chemicals, thereby improving the water resistance and corrosion resistance of the PIN. By improving the water resistance and corrosion resistance of the PIN, sealant can extend the service life of the PIN and reduce damage and failure caused by environmental factors. Using sealant for protection is a simple and easy method that does not require special equipment or skills. Just choose the right sealant and apply it according to the correct steps.

Regular inspection and maintenance: During each regular inspection, the waterproof cover should be carefully observed for cracks, deformation or shedding, and the sealant should be checked for aging, cracking or failure. If any signs of damage or failure are found, it should be replaced immediately to ensure the waterproof performance of the relay. Secondly, it is also very important to regularly check the electrical parameters of the relay. Changes in electrical parameters can reflect the performance of the relay, such as coil resistance, contact resistance, operating voltage and release voltage. During the inspection, appropriate test instruments should be used in accordance with the test methods and standards specified by the manufacturer. If the test results do not meet the specified requirements, timely measures should be taken to repair or replace them to ensure that the electrical performance of the relay meets the use requirements. In addition, it is also essential to perform functional testing on the relay. Functional testing can verify whether the relay operates and releases normally under specific conditions, and whether there are any potential faults or abnormalities. During the test, actual working conditions should be simulated, such as applying different voltages, currents and loads, etc., to verify whether the various functions of the relay are normal. If any faults or abnormalities are found, they should be stopped from use immediately and repaired or replaced.

Improve environmental conditions: If possible, try to reduce the humidity in the environment, such as by installing dehumidification equipment or strengthening ventilation. Keep the environment around the relay clean and avoid the accumulation of dust and dirt, which helps reduce the risk of corrosion and short circuits.

Select suitable electrical components and structural materials: When designing circuits, select electronic components and structural materials with low hygroscopicity to reduce the impact of moisture on the circuit.

Pay attention to the standardization of operation and maintenance: When installing, using and maintaining relays, the requirements in the operating procedures and maintenance manuals should be strictly followed to avoid damage to the relay or performance degradation due to improper operation.

Through the comprehensive application of the above measures, the telecommunication relay PCB PIN HLS6-4100H-1 can be effectively protected from corrosion or short circuit in a high humidity environment to ensure its normal operation.

Web Menu

Product Search

Exit Menu

news

Home / News / Industry News / How should this telecom relay PIN be protected from corrosion or short circuit in a high humidity environment?

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsHow should this telecom relay PIN be protected from corrosion or short circuit in a high humidity environment?

Posted by Admin | 03 Jun

PREV:Why are silver and gold chosen as the contact materials for this telecom relay?

NEXT:How to choose appropriate Relay Sockets Bases to optimize the performance of electrical control systems?

NEXT:How to choose appropriate Relay Sockets Bases to optimize the performance of electrical control systems?

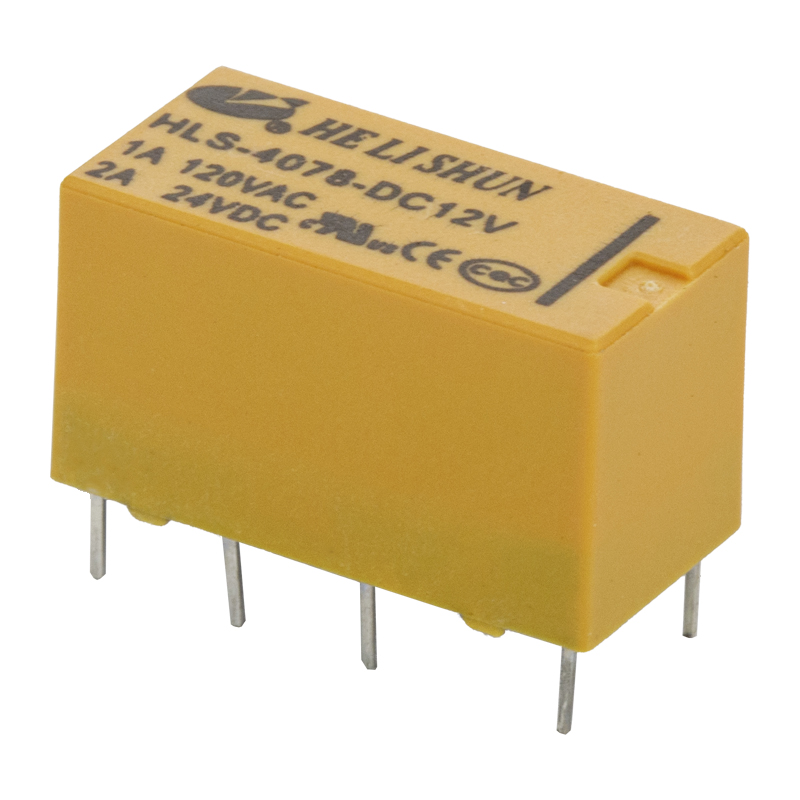

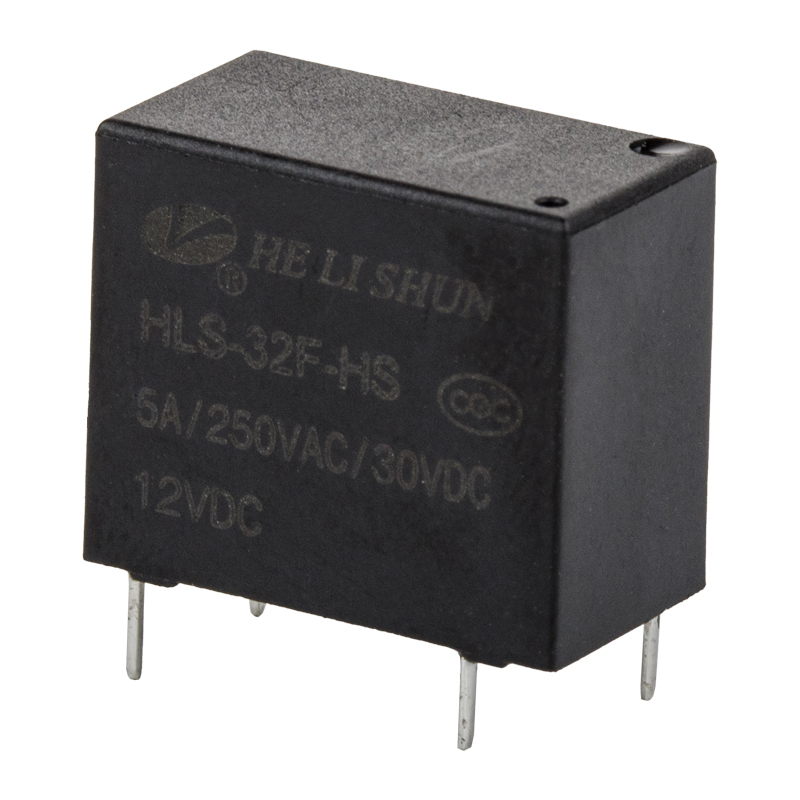

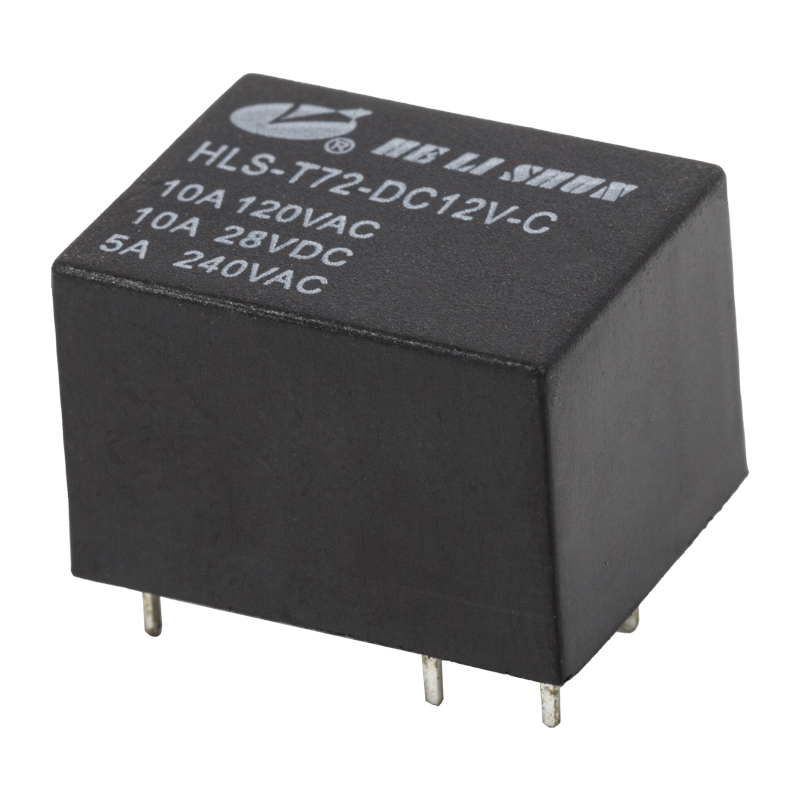

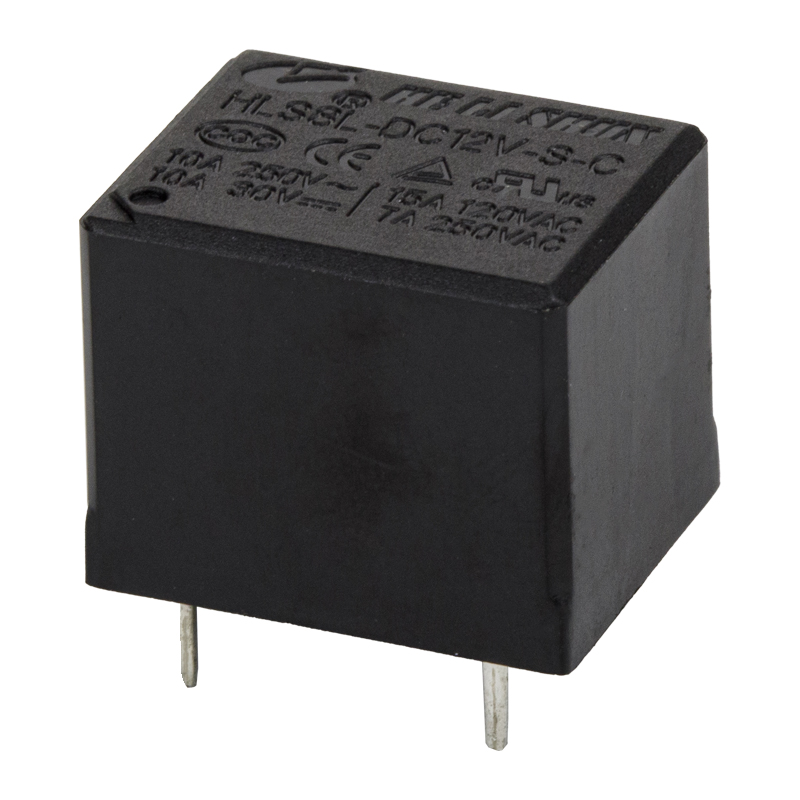

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright ? Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体