In electrical systems, Relay Sockets Bases play a key role in connecting and supporting relays. Among them, its performance in high-current and high-temperature environments is particularly important, as these conditions can pose challenges to electrical equipment. This article will take an in-depth look at the performance of Relay Sockets Bases in high current and high temperature environments, as well as their special design.

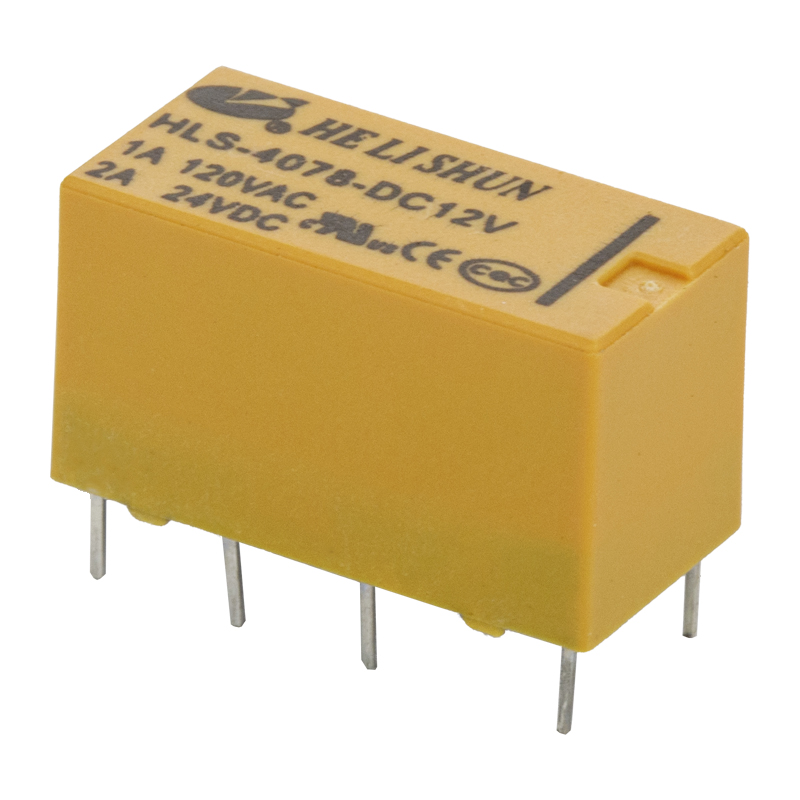

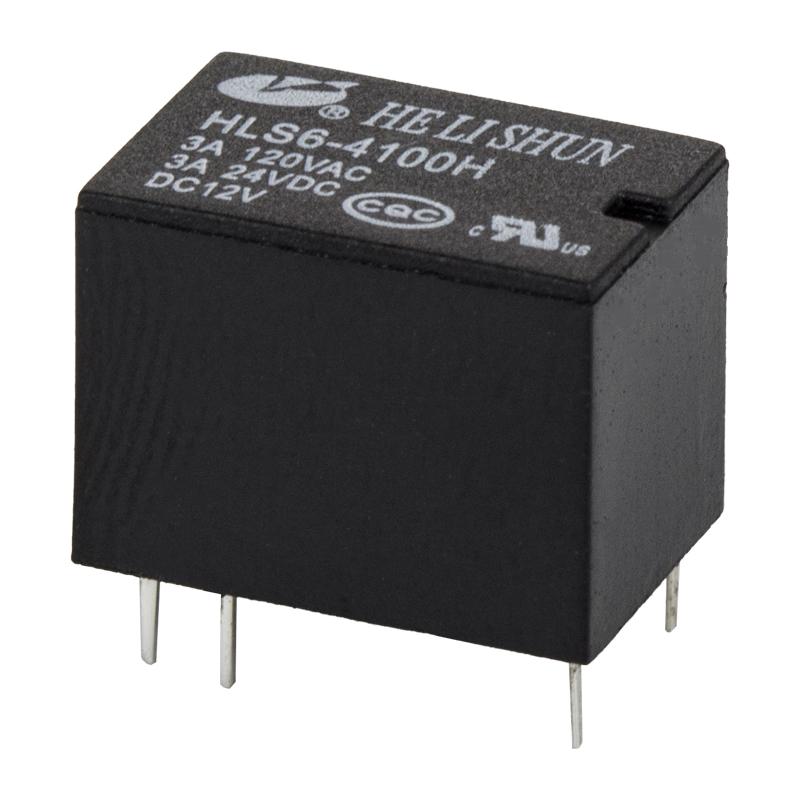

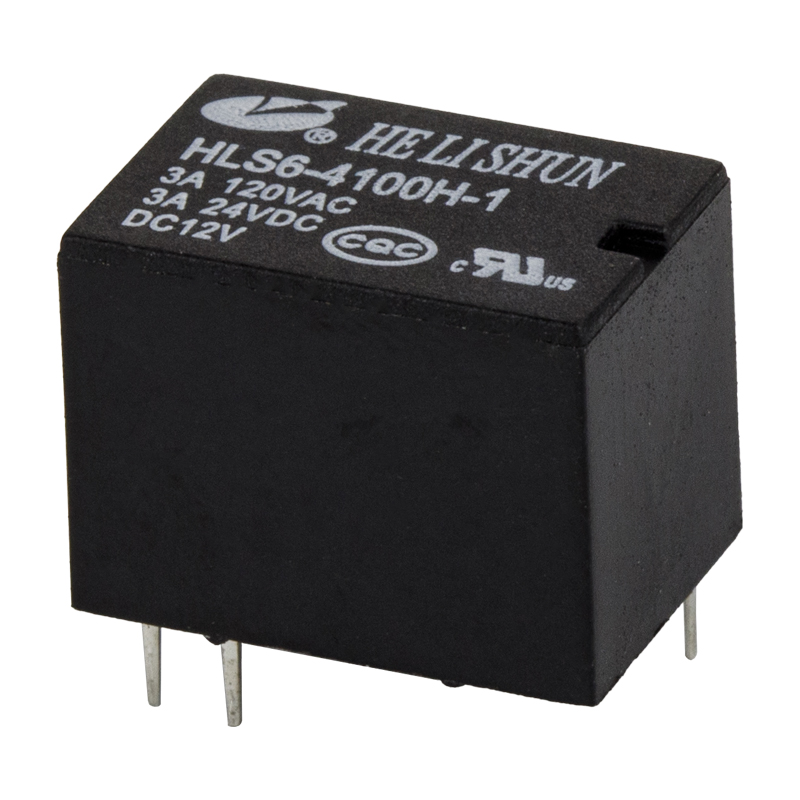

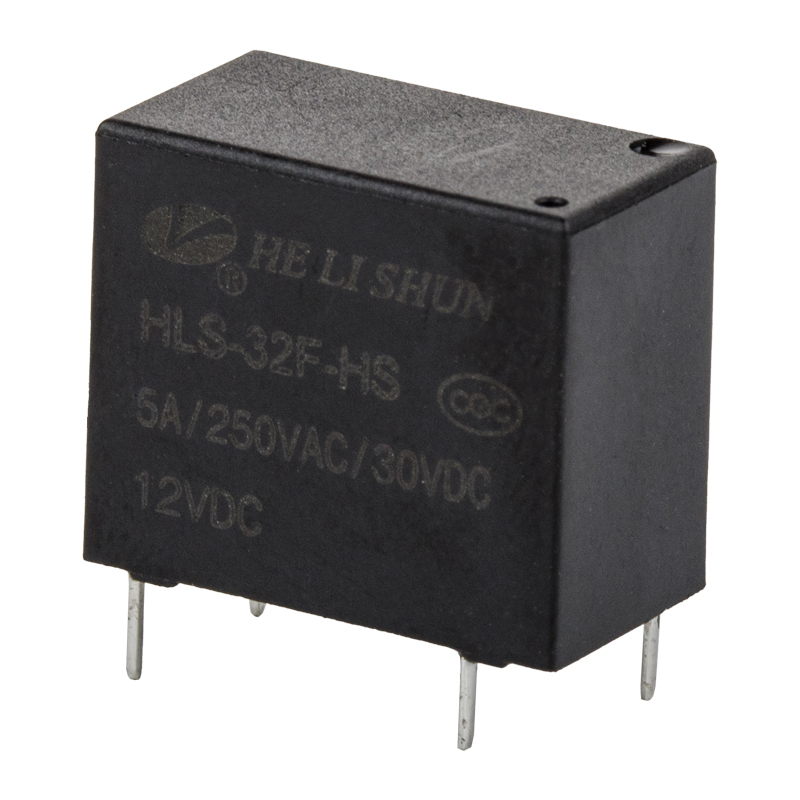

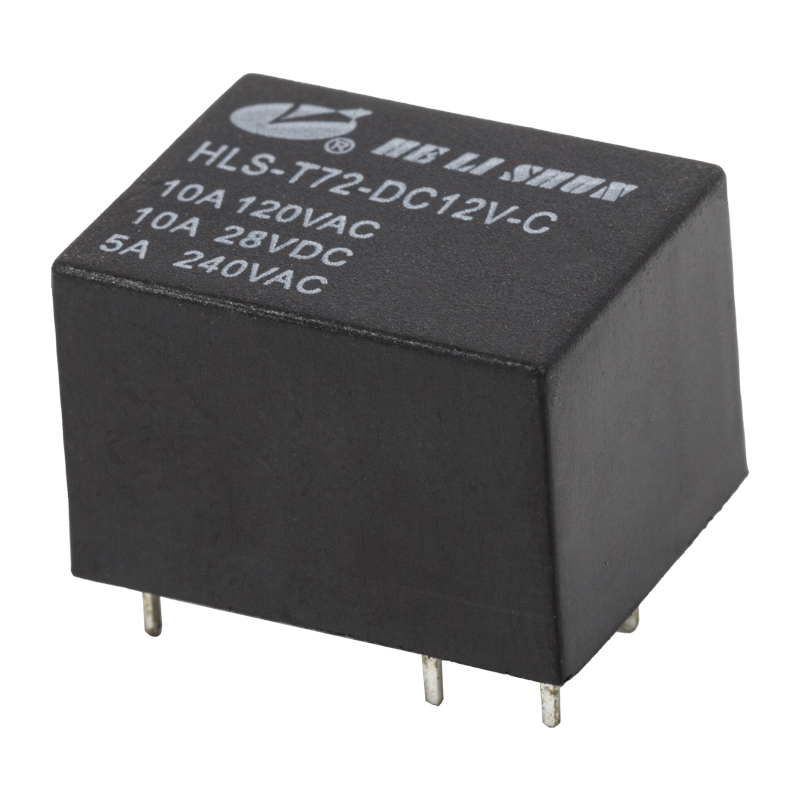

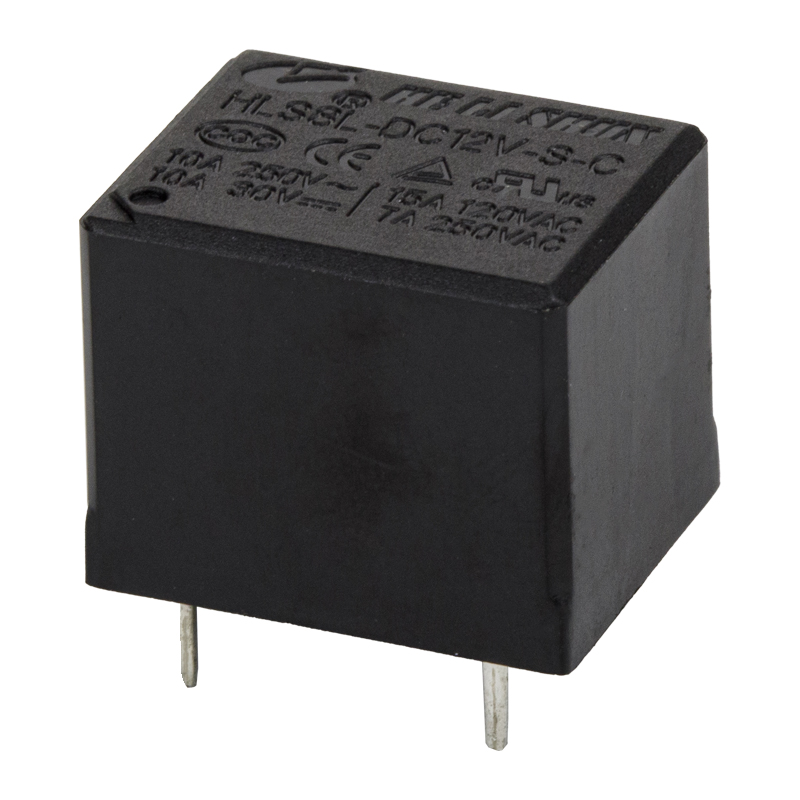

Relay Sockets Bases are bases for mounting and connecting relays. Not only do they provide a mechanical support and mounting location, they also connect the relay to the circuit of the electrical system through conductive elements. In electrical systems, Relay Sockets Bases are responsible for transmitting current and providing good electrical contact to ensure that relays can work properly.

In high current environments, Relay Sockets Bases must be able to effectively withstand and conduct large currents without generating excessive heat. Its performance depends on the selection of conductive materials, the design of the connection interface and the optimization of thermal conductivity. Some advanced Relay Sockets Bases use materials with high thermal conductivity, such as copper alloys, to ensure stable working conditions under high current loads.

In high temperature environments, Relay Sockets Bases need to have good heat resistance to prevent the material from softening, oxidizing or deforming. The special design takes into account the impact of temperature on plastic and metal materials, using high-temperature-resistant engineering plastics or heat-resistant alloys. These designs enable Relay Sockets Bases to maintain structural stability and electrical performance in high temperature environments.

In special designs, the heat dissipation structure is one of the key factors. High current and high temperature environments will generate a lot of heat, so Relay Sockets Bases need to design an effective heat dissipation structure to ensure rapid heat transfer and dispersion and avoid local overheating.

Material selection is another important aspect. Use materials with high temperature resistance and high thermal conductivity, such as ceramics, high-temperature plastics or metal alloys, to ensure performance under extreme conditions.

The compact design can increase the surface area for better heat dissipation, while reducing the size to adapt to high-temperature and high-density environments.

Dust and water resistance is another aspect of the special design. High-temperature environments may be accompanied by dust and moisture, so Relay Sockets Bases usually have a dust-proof and waterproof design to maintain their stability and durability.

In summary, the performance design of Relay Sockets Bases in electrical systems is directly related to the stability and reliability of the entire system. Facing high current and high temperature environments, its special design includes factors such as heat dissipation structure, material selection, compact design, and dustproof and waterproof to ensure that it can still work efficiently under extreme conditions. These special designs make Relay Sockets Bases an indispensable component in the electrical system, providing a solid foundation for the safe operation of the system.

English

English 中文简体

中文简体