During the maintenance process of automobile electrical systems, effectively checking and testing the performance of relays is a key step to ensure the normal operation of the vehicle and prevent potential problems. Relays perform important tasks in electrical systems, so regular inspection and testing of relay performance is crucial to maintaining system reliability. Here are some practical methods and steps to help you perform effective relay inspection and testing.

1. Visual inspection:

To begin, perform a visual inspection to ensure there is no physical damage to the relay or connection issues. Check that the contacts are clean and look for any unusual signs of scorching or wear. At the same time, check whether the relay's fixing screws and connecting wires are tight.

2. Resistance test:

A resistance test using a multimeter is an easy way to check if a relay is functioning properly. Set the multimeter to resistance measurement mode and connect the measurement leads to the relay's contacts. Normally, a good relay should show a low resistance value, close to zero ohms.

3. Voltage test:

Use a multimeter to perform a voltage test to check that the relay is operating at the correct voltage. Connect the multimeter's voltage leads to the relay's control terminals and turn on the vehicle's power. Observe the voltage reading to make sure it is within normal operating range.

4. Trigger test:

Conduct a trigger test to verify that the relay can be activated under normal operating conditions. Observe the operation of the relay and listen for the click of the contacts by connecting the appropriate supply voltage to the relay's control terminals. If the relay fails to trigger, it may indicate a faulty or damaged relay.

5. Temperature test:

Relays can be affected by temperature when operating, so temperature testing is important. By letting the relay operate for a period of time, then measure its surface temperature with a thermometer. Excessively high temperatures may indicate a problem with the relay.

6. Exchange test:

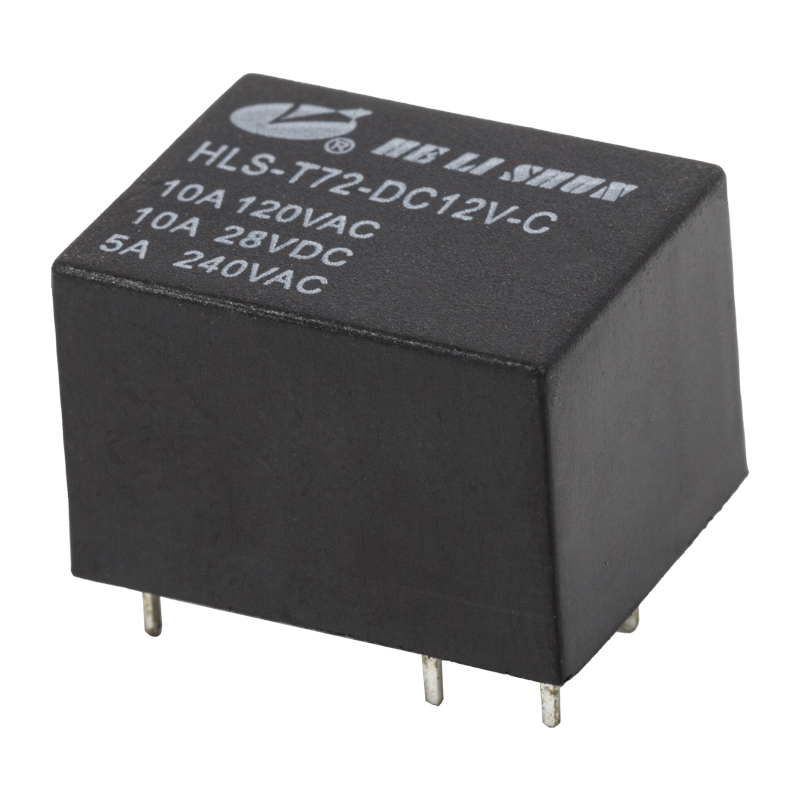

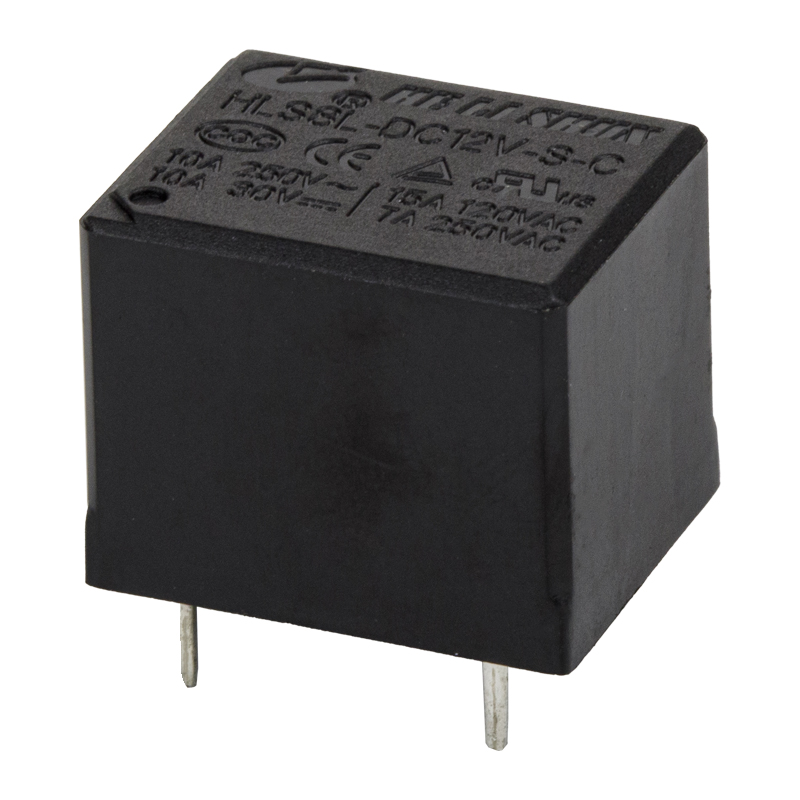

For multiple relays of the same model, exchange testing can be performed. Swap a functioning relay with the relay that needs to be tested and see if the problem is solved after the problematic relay is replaced.

7. Professional equipment testing:

If possible, use professional relay testing equipment for more comprehensive testing. These devices are capable of simulating different operating conditions, ensuring that the relays will function properly in a variety of situations.

When performing relay inspection and testing, always make sure power is disconnected from the vehicle to avoid electric shock and other safety risks. If any problems are found during inspection and testing, it is recommended to replace the relay in time to ensure the stable operation of the vehicle's electrical system. Through regular maintenance and inspection, the reliability of the relay can be improved, its service life can be extended, and the long-term healthy operation of the vehicle electrical system can be ensured.

English

English 中文简体

中文简体