As a key electronic component, telecom relays play a vital role in the fields of communications, control systems and automation. Their design needs to consider a variety of environmental factors to ensure stable and reliable operation under various conditions. Telecom relays can maintain their best working conditions in an environment with a relative humidity of 40% to 85%. This range is the result of comprehensive consideration of the material properties, structural design and application scenarios of telecom relays. Within the appropriate humidity range, the electrical contacts, insulating materials and mechanical structures inside the telecom relay can maintain optimal performance, thereby ensuring the accuracy and stability of signal transmission.

When the ambient humidity exceeds 85%, the electrical contacts inside the telecom relay are prone to oxidation due to moisture, resulting in increased contact resistance, which in turn affects the transmission quality and speed of the signal. At the same time, high humidity may also cause the performance of the insulating material to deteriorate, increasing the risk of electrical breakdown.

The mechanical structure of the telecom relay is also easily damaged in a high humidity environment. For example, metal parts may be deformed due to corrosion, resulting in inflexible movement or failure. In addition, high humidity may also affect the sealing performance of the relay, making it vulnerable to external contaminants.

Long-term operation in a high humidity environment will accelerate the aging process of the internal parts of the telecommunications relay. This includes wear of electrical contacts, degradation of insulating materials, and fatigue of mechanical structures. These aging phenomena will directly affect the service life and reliability of the telecommunications relay.

In an environment with high humidity, dehumidifiers, desiccant and other moisture-proof devices can be installed for the telecommunications relay to reduce the humidity level in the environment. At the same time, you can also consider using a relay housing with better sealing performance to reduce the intrusion of external moisture. When purchasing telecommunications relays, you should give priority to products with a high protection level. These products usually have better moisture, corrosion and dust resistance, and can maintain stable performance in harsh environments.

Regular inspection and maintenance of telecommunications relays is an important measure to ensure their normal operation. This includes checking the wear of electrical contacts, cleaning dust and contaminants inside the relay, and replacing aging or damaged parts. Where possible, the working environment of telecommunications relays should be optimized to reduce the impact of adverse factors such as humidity, temperature and contaminants. For example, the ambient humidity and temperature can be controlled by installing equipment such as air conditioners and dehumidifiers; at the same time, the working area should be kept clean and tidy to reduce the intrusion of external contaminants.

Telecom relays can maintain optimal working conditions in an environment with a relative humidity of 40% to 85%. However, in a high humidity environment, the electrical performance, mechanical performance and service life of telecom relays may be adversely affected. Therefore, in order to ensure the stable operation of telecom relays and extend their service life, necessary moisture-proof measures and maintenance recommendations should be taken.

Web Menu

Product Search

Exit Menu

news

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86-0574-88473018 Contact UsAt what relative humidity can a telecom relay operate normally?

Posted by Admin | 16 Oct

PREV:Under what conditions can this high power relay guarantee its optimal performance?

NEXT:What positive effects does silver alloy, as a contact material, have on the performance of automotive relays?

NEXT:What positive effects does silver alloy, as a contact material, have on the performance of automotive relays?

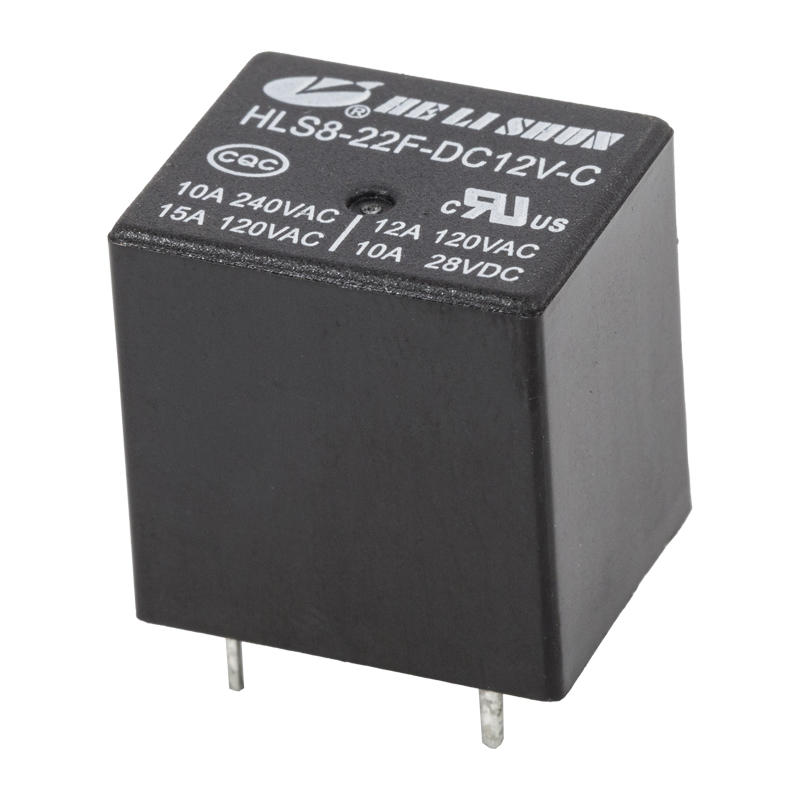

Related Products

-

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

Hehuaqiao,Yunlong,Yinzhou District,Ningbo,Zhejiang

-

Tel:+86-0574-88473018

Tel:+86-0574-88473018

+ 86-0574-88344018 -

Fax:+86-574-88345918

Fax:+86-574-88345918

-

E-mail: sales@helishun.com

E-mail: sales@helishun.com

sales2@helishun.com

About us

Ningbo Helishun Electron Co.,Ltd. is founded in 2000, located at Ningbo City, the Grand East port on the coastline of the East Sea. We are OEM/ODM Electromagnetic Relays Manufacturers in China

Extra links

QR code

Copyright © Ningbo Helishun Electron Co.,Ltd. All Rights Reserved. Electrical Relays Suppliers

English

English 中文简体

中文简体